Fine chemistry

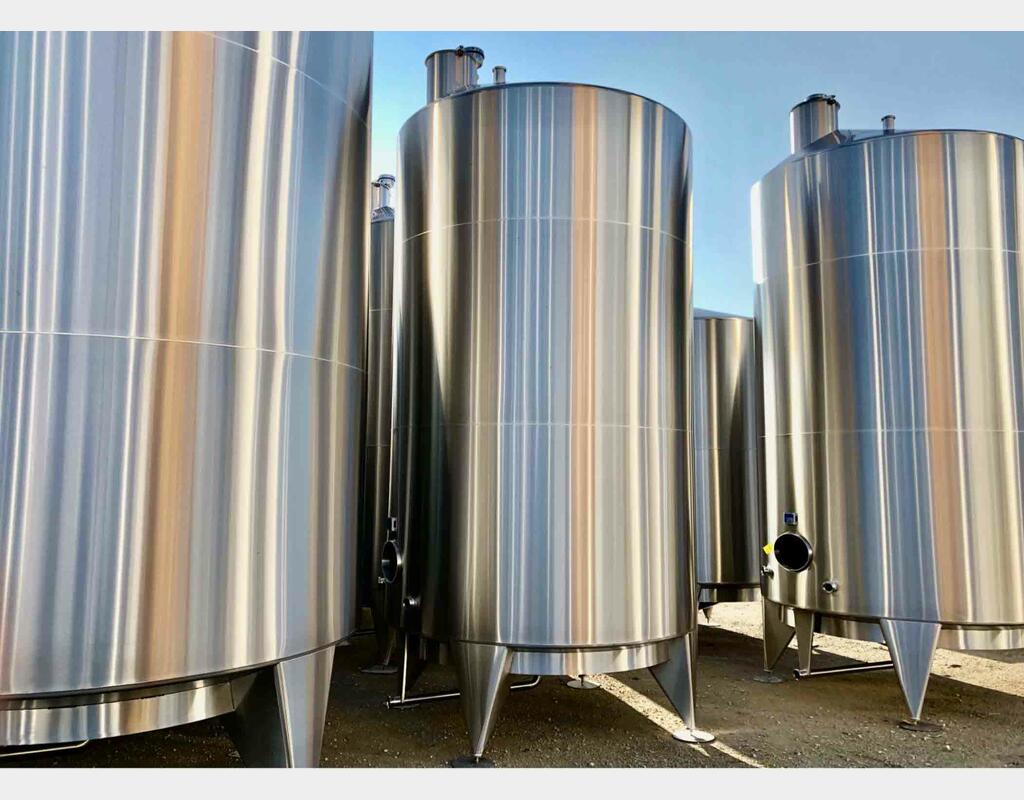

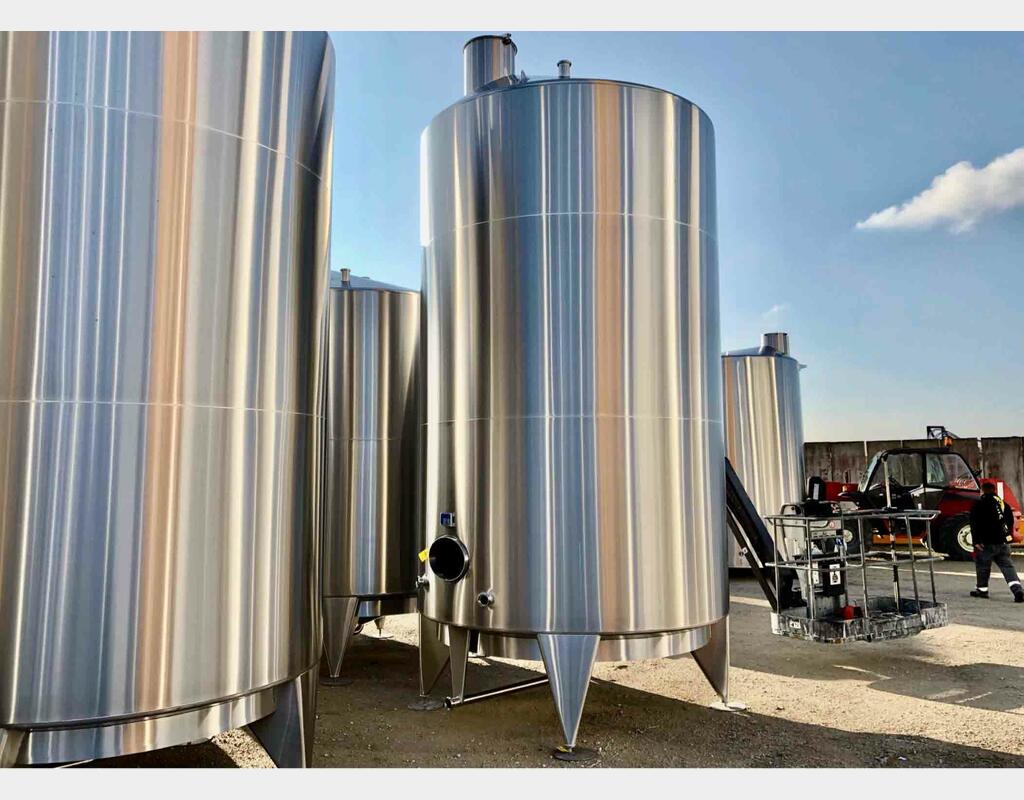

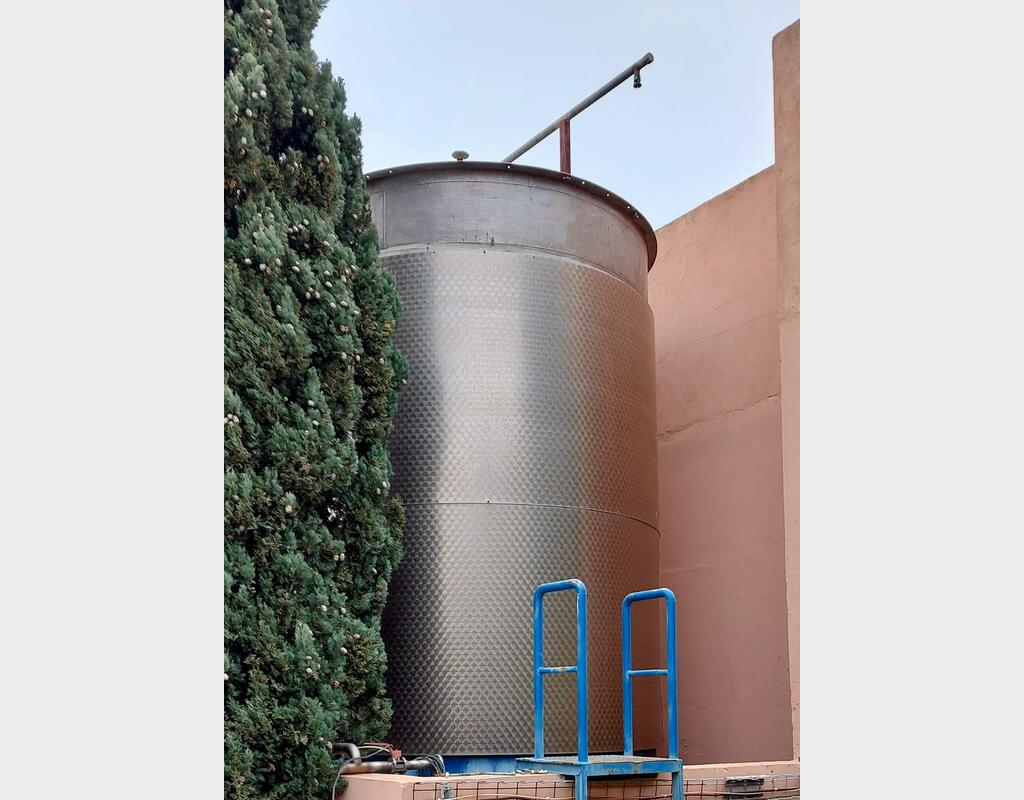

Stainless steel tanks for fine chemicals : reaction, mixing and storage

Chemical processing, mixing, storage & processing, temperature control, all capacities.

Fine chemicals require safe, traceable equipment that is suitable for corrosive environments and solvents. 304/316L stainless steel tanks are used for synthesis, mixing, crystallisation and storage, with options for agitation, heating/cooling (double jacket/coil), inerting and CIP. Regulatory compliance (food contact if required, ATEX, PED) and sanitary finish facilitate cleaning and risk control. This page centralises the recommended configurations and provides direct access to stock (new & used) as well as trade-in services.