TIP - Mounting a floating cap on a tank

Installation of the mobile ceiling on a stainless steel vinification tank

Floating top wine racks transform tanks into containers of variable capacity for fermentation as well as short and long term storage of wine. This type of mobile ceiling tank is mainly used in the wine industry, but it is also used in many other food sectors. Although we are using a stainless steel tank in this example, the system also works with other types of vats, such as fibreglass resin. The lid is simply inserted inside the tank and floats on the surface of the wine. An air chamber around the lid is inflated to create an airtight seal. Here are our tips and tricks for using a floating cap on a stainless steel tank for winemaking or wine maceration.

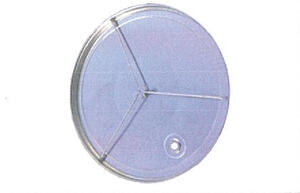

The floats, two types of floating hats for stainless steel wine guard

There are two types of floats that can be mounted on an inner tube.

|

The pneumatic float ′′ molded ′′ • From + 380 à 2070 • Available with draws • Available with PVC vent valve |

|

′′ Welded ′′ pneumatic float • From + 2190 à 2550 • Available with draws • Available with PVC vent valve |

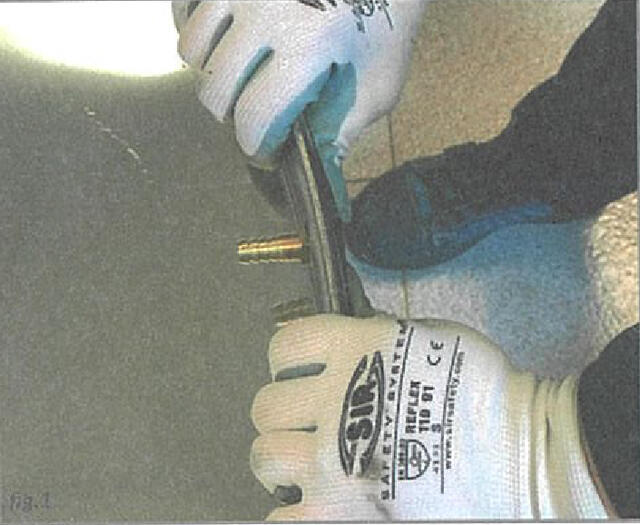

Installation of the tubes on the float

It is necessary for the assembly of the tub on the floating hats to have two operators available.

WARNING

It's important to use the necessary PPE.

|

|

|

|

|

|

|

Operator 1-2 : Once the inner tube is inserted at least half the float, pull it until it is fully recessed. |

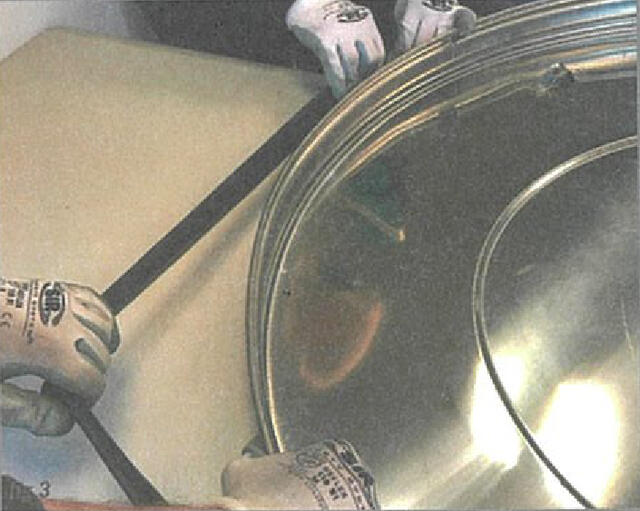

Setting up and installation of the float in a stainless steel tank

|

Please follow the following instructions carefully :

• Filling the moving ceiling tank;

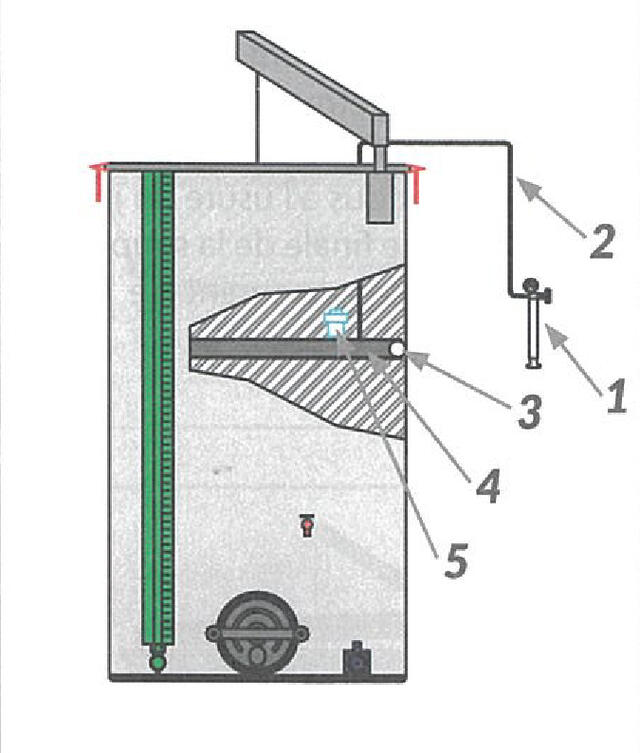

• Place float (4) with tubes (3) and PVC ventilation valve (5) onto the wine surface;

• Inflate the inner tube using the pump provided (1) at a pressure of approximately 7 atm;

• Check that the tubes are evenly inflated and sealed perfectly throughout the tank wall.

|

|

|

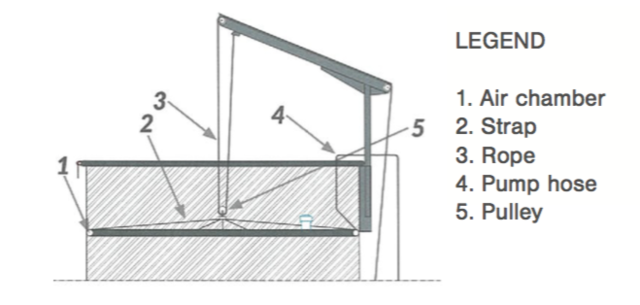

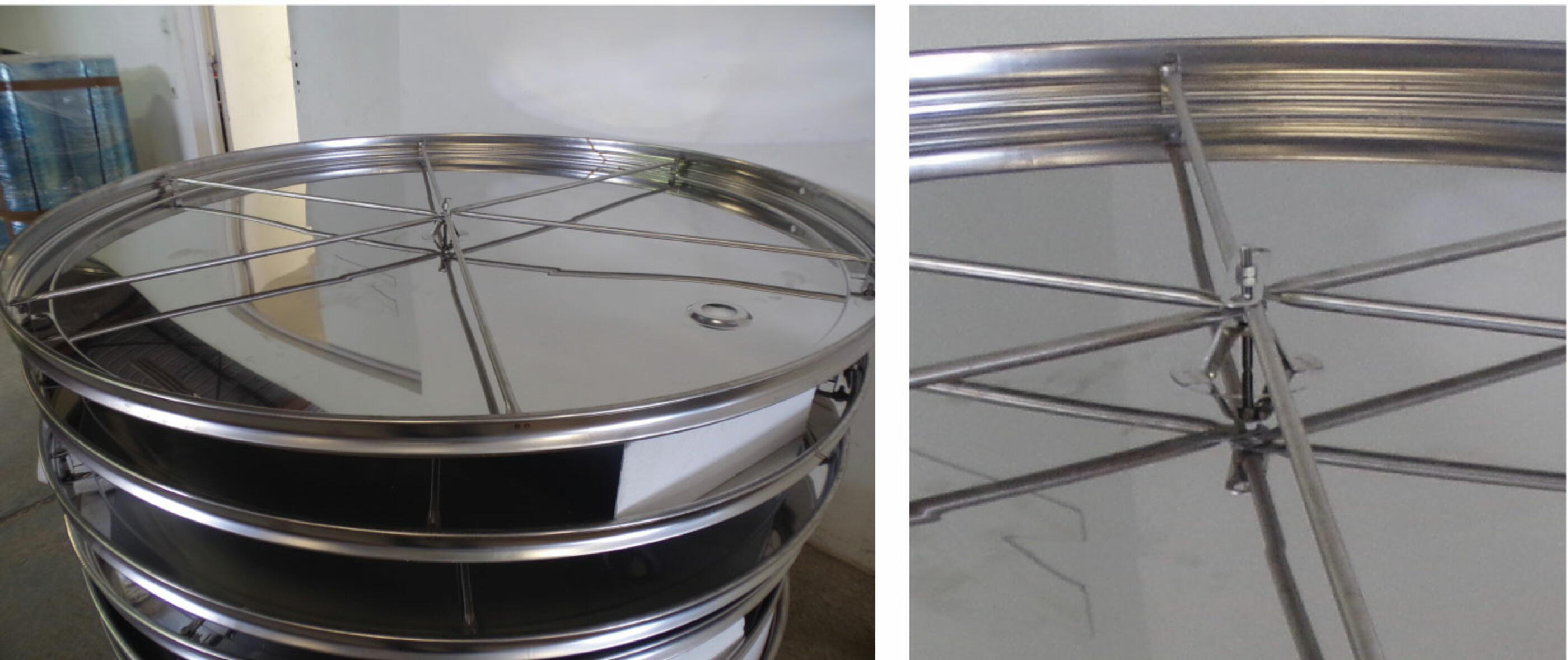

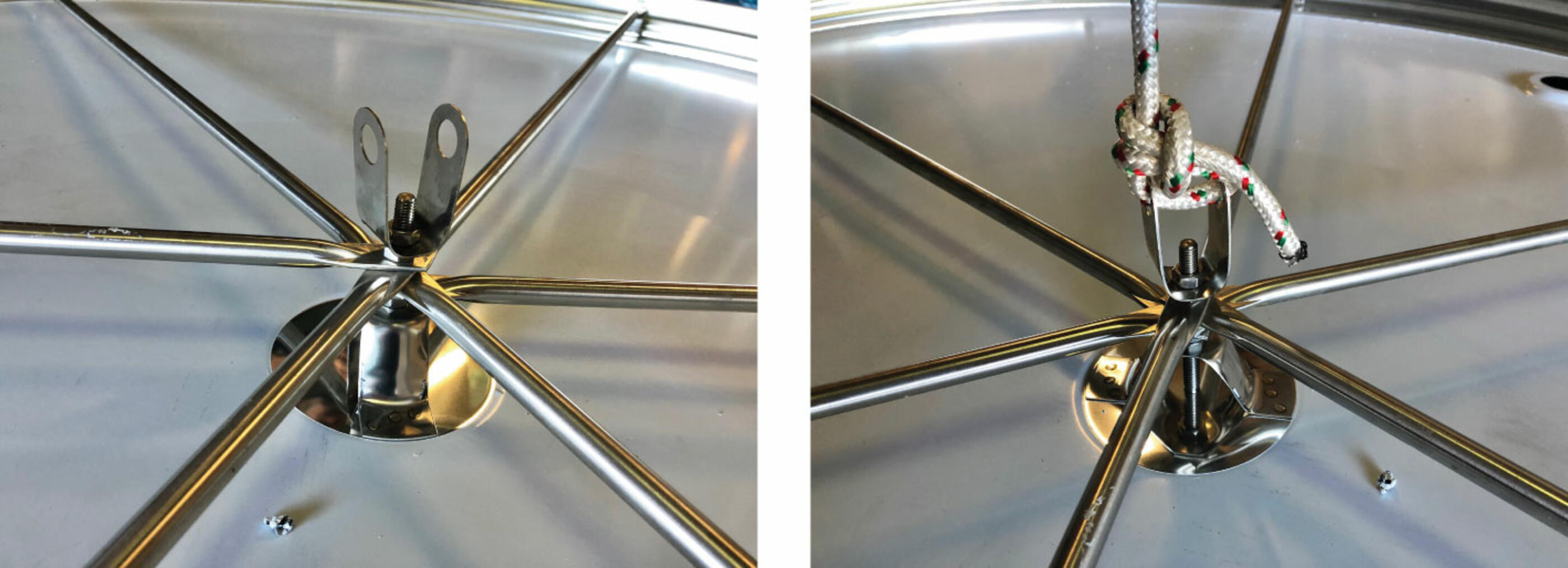

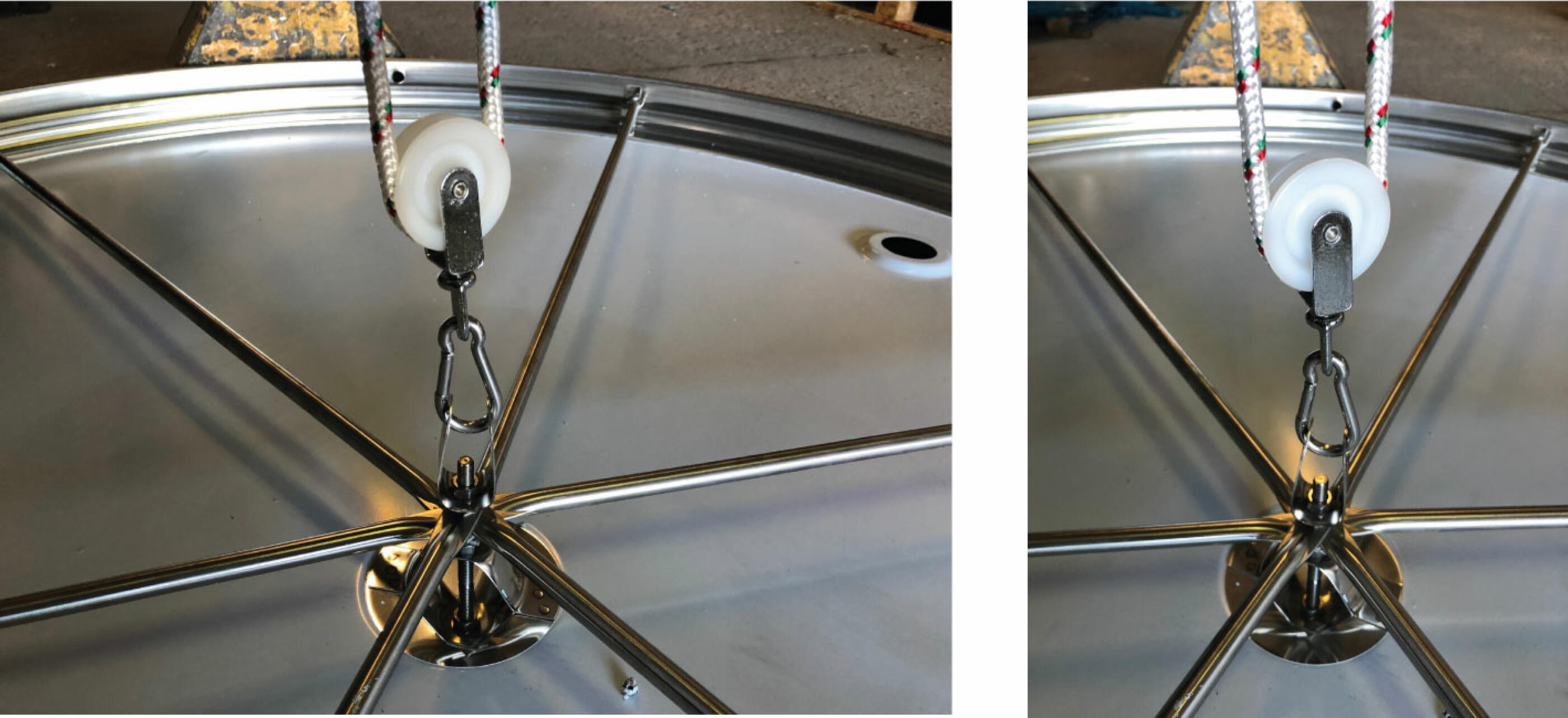

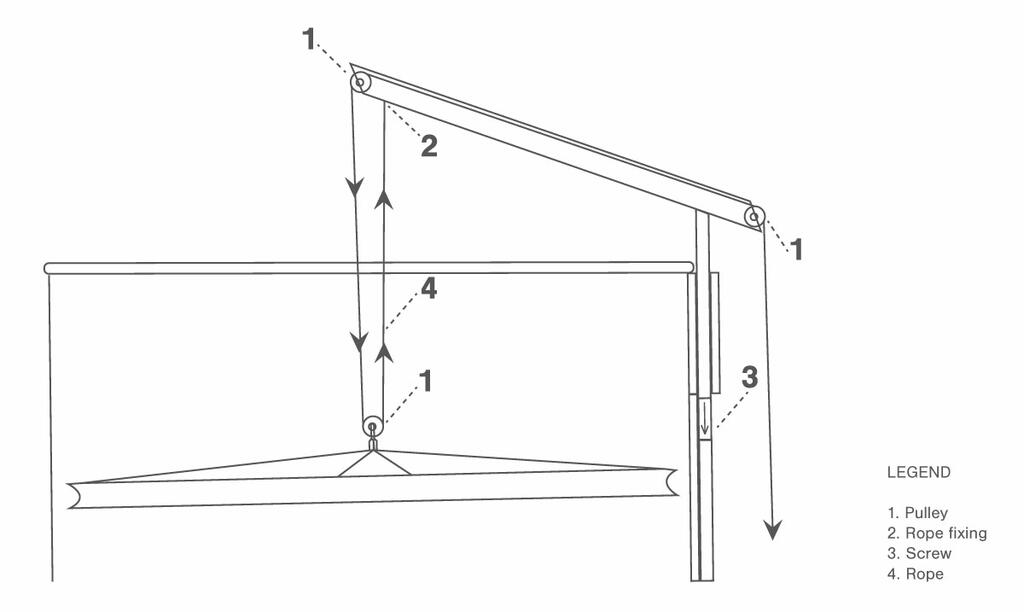

Put the float properly installed on the floor and insert the pulley as shown in the above diagram.

With the pulley, carry the float over the tank and slow down inside. Pay special attention and never stay below the float as shown in Figure 2 on the left. Always use PPE and pay very attention.

WARNING

Tubes should be sealed periodically and at least every 7 days.

If the pressure of the tubes is not enough, check :

• No holes;

• The absence of leakage between the tubes and the pipe;

• The pipe clamps are tight

• That the pressure gauge works perfectly;

• Pump steering wheel tight

MAKE THESE CONTROLS REMEMBER TO AVOID ACCIDENTS

Editing the gallows

Pulley from dimaeter 1800

|

|

|

The importance of pump revision

|

O-rings or pump seals should be cleaned or greased with food oil or vaseline grease every 6 months.

If consumed, broken or otherwise damaged, they need to be replaced immediately.

Malfunctions are normally due to O-ring wear on the final part of the air intake and exhaust valve.

|

O-rings from the pump air removal steering wheel should be washed and greased with vaseline every 6 months.

They need to be replaced when consumed.

• If they get out of their seat, they break;

• If not greased, they stick, skate and break;

• And the valve loses.

Lubricating should be done periodically to avoid malfunction.

The whole Arsilac team wishes you a good installation and do not hesitate to contact us if you have any questions.