TIP - Agitators : Tank equipment

Key elements for choosing the right equipment

In the processing industries, the choice of tank equipment is essential to maintain the homogeneity of existing mixtures, suspensions or emulsions. Unlike industrial mixers, which are designed to quickly mix two or more components, agitators are specifically designed for this task.

→ Discover the mixers available in stock

PROPELLER SHAKERS

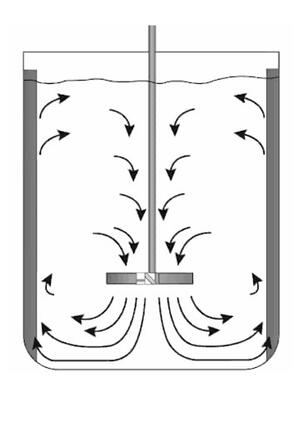

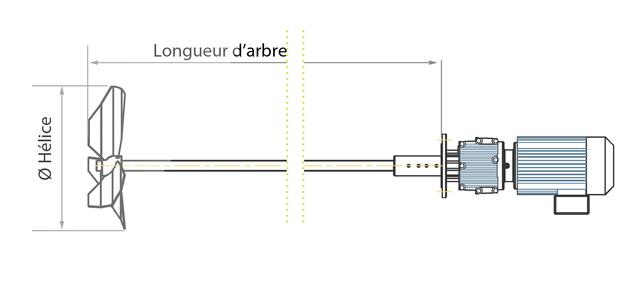

Agitators are equipment used to homogenise materials within a tank for mixing. They operate by rotating the impeller at their immersed end at a controlled speed, which induces flow and shearing of the material within the tank. Propeller agitators, for example, allow single or multi-component materials to be homogenised in a uniform and controlled manner.

|

|

|

We offer a propeller agitator solution, a modular system mounted on industrial process tanks, such as stainless steel vessels. Our range of agitators are specifically designed to provide maximum mixing effect through smooth and controlled rotation, whilst minimising energy consumption and equipment wear.

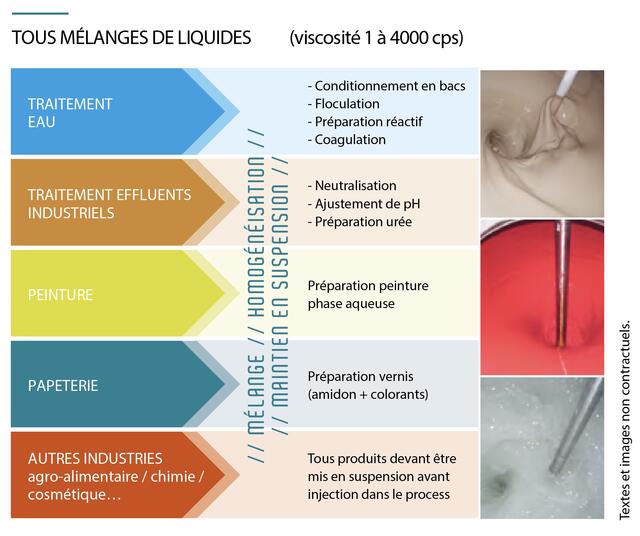

MIXING

Mixing is the process of obtaining a uniform final product from two or more dissimilar parts of materials. Agitators are used in many sectors and industries, such as cosmetics, pharmaceuticals, research, laboratories, chemicals, agriculture, food, beverages, pulp and paper.

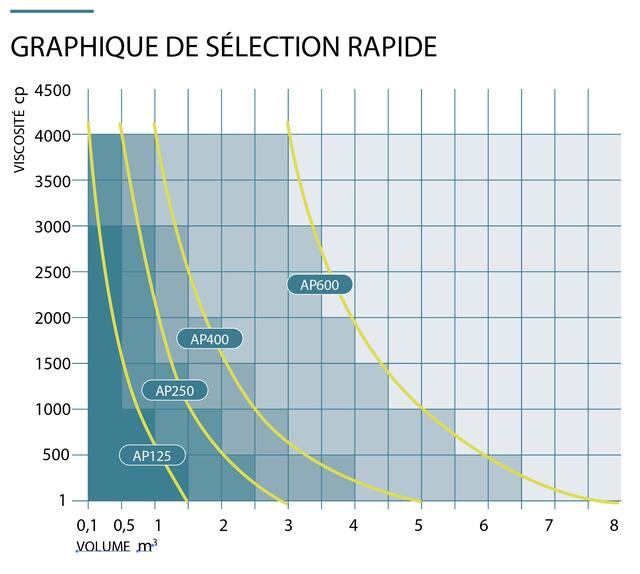

VISCOSITY

Viscosity is an important property to consider when choosing the right agitator for your needs. Viscosity is the resistance of a liquid to flow and varies with the temperature of the product. The higher the viscosity, the greater the mechanical energy transmitted by the rotary agitator to achieve a sufficient flow state.

Low viscosity liquids have little resistance to flow and therefore require relatively small amounts of energy per unit volume for a mixing condition to occur. High viscosity liquids attenuate the mechanical energy imparted by a rotating agitator and require relatively large amounts of power per unit volume to achieve a sufficiently large flow condition for adequate mixing to occur.

Viscosity is measured in Pascal/second or centipoise.

1mPascal/second = 1 centipoise (symbol: Cp)

1 Pascal/second = 1000 Cp

A product such as salad dressing will have a viscosity of between 1300 and 2600 mPa/s (Cp); that is, between 1300 and 2600 centipoise or between 1.3 and 2.6 pascal/sec.

It is important to take into account the following situations:

- If the temperature of the product being mixed increases, then the viscosity of the material will decrease and the liquid will become more fluid;

- If the motor speed decreases, then the agitator can work with thicker products and thus mix higher viscosities.

FOR A TEMPERATURE MAINTAINED AT 23°, HERE ARE THE VISCOSITIES WE KNOW OF :

| - Water = 1 Cp - Ethanol = 1 cp - Milk = 2 to 10 Cp - Fruit juice = 2 to 5 Cp - Olive oil = 85 to 100 Cp - Liquid cream = 10 Cp - Linseed oil = 28 Cp - Glycol = 40 Cp - Palm oil = 45 Cp - Peanut oil = 40 Cp - Coconut oil = 60 Cp - Corn oil = 72 Cp - Soup = 85 Cp - Olive oil = 80 to 100 Cp - Castor oil = 100 Cp - Molasses with 65% sugar = 120 Cp - Hydraulic oil = 120 Cp - Engine oil SAE 10 = 85 to 140 Cp - Yoghurt = 150 Cp - Engine oil SAE 20 = 140 to 420 cps - SAE 30 engine oil = 420 to 650 cps - SAE 40 engine oil = 650 to 900 cps - Rapeseed oil = 160 - Chocolate sauce = 280 cp - Engine oil SAE 15W40 = 390 Cp - Molasses with 70% sugar = 400 Cp - Liquid wax = 500 Cp - Fruit must = 600 Cp - Motor oil SAE 40 = 650 - 900 Cp - Varnish = 900 Cp |

- Ketchup = 1000 Cp - Dressing, salad dressing = 1300 to 2600 Cp - Baby food = 1400 Cp - Glycerine = 1500 Cp - Chocolate mousse = 1500 Cp - Apple puree = 1500 Cp - Mayonnaise = 2000 cp - Fruit juice concentrate = 2500 Cp - Shampoo = 3000 Cp - Polyester resin = 3000 Cp - Maple syrup = 2500 to 5000 Cp - Condensed milk = 6000 Cp - Hand cream = 8000 Cp - Jam = 4000 to 8500 Cp - Malt extract = 9500 Cp - Liquid honey = 6000 to 10000 Cp - Soft cheese = 30,000 Cp - Butter = 30,000 cp - Mustard = 70,000 Cp - Toothpaste = 70,000 Cp - Sour cream = 100 000 Cp - Tar 100 000 to 10 000 000 Cp - Peanut butter = 250 000 Cp - Lard = 1 000 000 Cp - Putty = 100 000 000 Cp - Pitch = 2 300 000 000 Cp |

The propeller agitators we offer are used to process low viscosity substances such as liquids, to homogenise, suspend or disperse materials. Our axial flow agitators are ideal for solid suspensions in liquids as they prevent the deposition of solid particles.

Axial flow turbines flow the fluid parallel to the turbine's axis of rotation. These turbines have inclined blades that are less than 90° to the plane of rotation. The rotation of the turbine causes a cyclic flow pattern from top to bottom. The fluid at the top of the tank is forced to flow until it is diverted to the bottom of the tank. It then spreads out from the bottom of the tank and flows up the wall before being drawn in by the turbine. This movement mixes the fluid from top to bottom and prevents solids and solutes from settling to the bottom of the tank.

HOW TO CHOOSE YOUR AGITATOR

Selecting and sizing a mixer can be a complicated decision. The specific design, operating arrangement and performance requirements of the agitators play a role in selecting the right equipment for the quality of the finished product.

To evaluate your needs, we take into account 3 criteria

- the nature of the bulk products to be mixed

- the purpose of the mixing

- the type of process and its environment

Find out more about the stirrers available in stock here.

Download the technical documentation here.

Do not hesitate to contact our team to discuss your project and define the most suitable equipment for your process.

#arsilac #agitateur #melange #cuve #process