Brewery

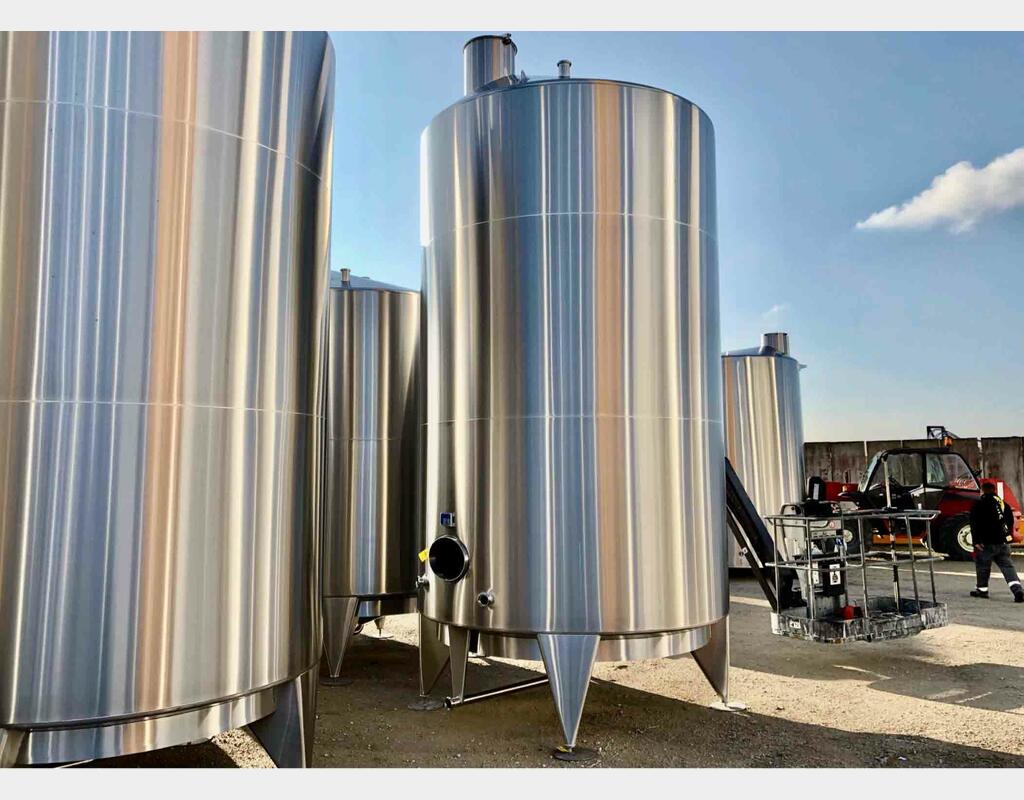

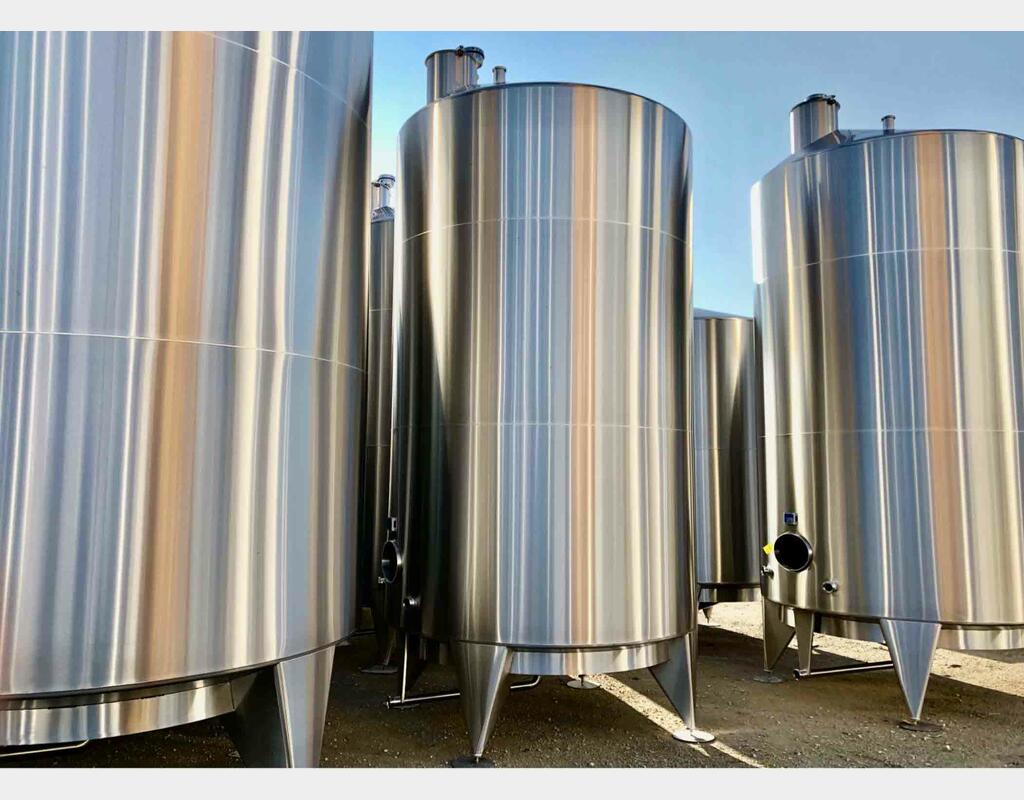

Stainless steel tanks for brewing, fermenting and storing beer

Beer fermentation, storage & ageing, temperature control, all capacities.

Stainless steel tanks for breweries cover the key stages: fermentation in cylindro-conical fermenters (CCT), conditioning in bright beer tanks (BBT) and refrigerated storage. Glycol jackets ensure temperature control; CIP integration facilitates hygiene. Accessories (doors, connections, carb stone, sampling ports) can be configured according to style and production rates.