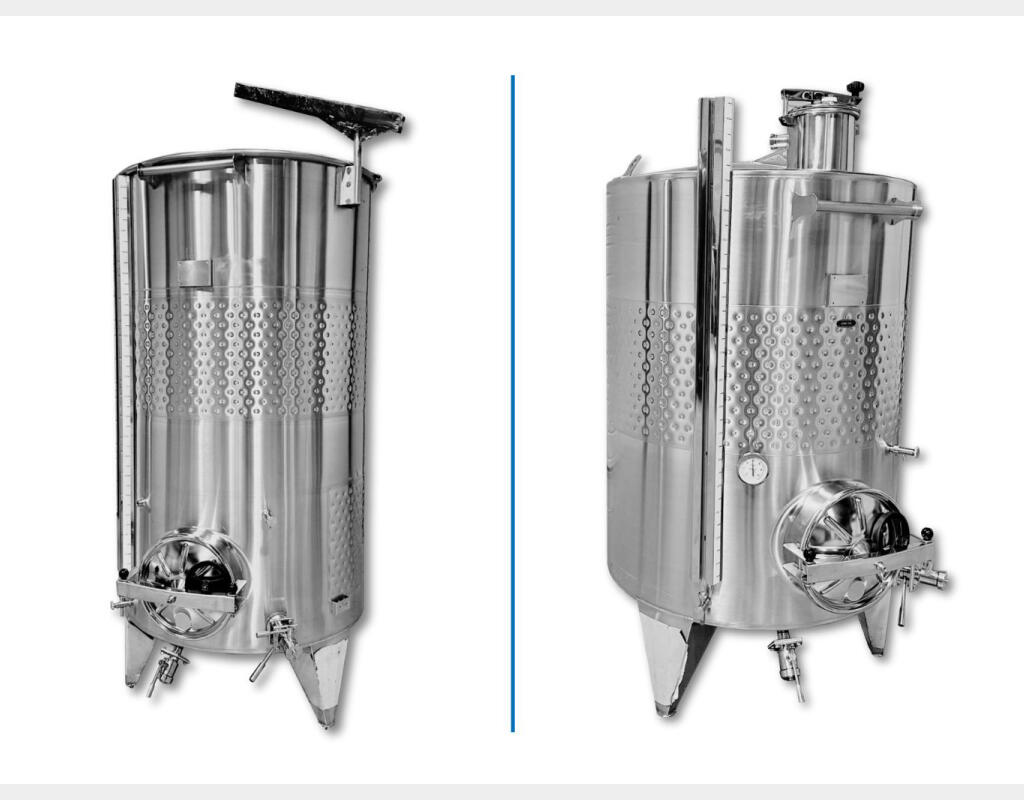

Mobile stainless steel palletised tanks

Practical and durable storage solutions

Mobile stainless steel tanks are an essential solution for storage and transport in the food, chemical, and pharmaceutical industries. Equipped with a palletized base, they are specifically designed for easy handling with a forklift — saving time and improving safety in production environments. Available by order only through the Arsilac catalog, these high-quality tanks are made from AISI 304 or 316 stainless steel and offered in a wide range of capacities, from 500 to 2,000 liters. Whether you're looking for a palletized stainless steel tank or a mobile tank with reinforced hygiene and mobility, our range meets the highest standards of cleanliness, durability, and industrial performance.

Why Choose a Mobile Palletized Stainless Steel Tank?

Easy and secure handling

Palletized stainless steel tanks are specifically designed for internal transport across industrial sites.

Thanks to their pallet-compatible base, they can be moved easily using a forklift or pallet jack — with no risk of tipping or deformation. This design streamlines logistics and reduces manual handling effort.

💡 Ideal for environments where mobility is essential: production lines, storage areas, and cleaning zones.

Hygiene and corrosion resistance

Made of AISI 304 stainless steel — or AISI 316 upon request — these tanks offer excellent resistance to corrosion, wear, and chemical exposure.

They are the go-to choice for the food and chemical industries, where robust, durable, and easy-to-clean containers are critical.

The cold-formed bottom, TIG-passivated welds, and smooth BA (Bright Annealed) internal finish ensure a seamless, hygienic surface — ideal for processes requiring strict sanitary standards.

Versatile designs with specialized lids

Mobile palletized stainless steel tanks are available with several lid types, tailored to specific applications:

- Dome lid with handle – for quick semi-open access

- Floating lid with air seal – for adjustable sealing

- Lever-lock lid – for optimal security during transport or processing

These options allow you to adapt the tank to your needs, whether for secure storage, product mixing, or safe movement.

Enhanced productivity and time savings

With easier transport, cleaning, and full drainage via butterfly or ball valves up to DN50, these mobile tanks help minimize production downtime and maintenance tasks. You gain efficiency and flow across your industrial processes.

sbp palletized stainless steel tank models – technical specifications

The SBP range of mobile stainless steel tanks offered by Arsilac is designed to meet the highest standards for liquid storage, handling, and transport across industrial sectors. Available in capacities from 500 to 2,000 liters, these tanks combine durability, safety, and ease of use.

Model overview and specifications table

| Model | Capacity (L) | Height (mm) | Weight (kg) | Base Dimensions (mm) |

|---|---|---|---|---|

| SBP500 | 560 | 945 | 95 | 1135 x 1135 |

| SBP750 | 750 | 1150 | 103 | 1135 x 1135 |

| SBP1000 | 1010 | 1435 | 115 | 1135 x 1135 |

| SBP1250 | 1320 | 1775 | 129 | 1135 x 1135 |

| SBP1500 | 1550 | 2025 | 140 | 1135 x 1135 |

| SBP2000 | Up to 2,000 | On request | On request | 1135 x 1135 |

All tanks in this range feature a palletized base, allowing safe movement by forklift or pallet jack.

General technical specifications

- Main material : AISI 304 stainless steel (AISI 316 available on request)

- External finish : Satin-polished

- Internal finish : BA (Bright Annealed) – smooth surface for easy cleaning

- Bottom : Cold-formed with optimized profile, thickness ≥ 1.5 mm

- Welding : Automatic TIG welding, cleaned and passivated

- Drain valve : Ball or butterfly type, up to DN50 (2”), for full drainage

Accessories & custom options (on request)

Available lid types :

- Semi-opening with handle

- Floating lid with air chamber

- Lever-lock quick-close lid

|

|

|

||

Available options :

- Threaded or quick-connect fittings

- Level indicator

- Integrated agitator

- CIP (Cleaning-In-Place) system

- Thermal insulation or heating jackets

- Custom dimensions for specific needs

The SBP palletized stainless steel tanks are built to integrate seamlessly into your processes, thanks to a modular design and customizable options. Each model is engineered to deliver safety, durability, and efficiency — even in demanding industrial environments.

accessories and customization – sbp palletized stainless steel tanks

To meet the specific requirements of each industry, Arsilac’s SBP mobile palletized tanks are fully customizable. Every component can be adapted to ensure optimal use — whether for storage, mixing, transfer, or processing of liquids.

Fittings, valves & drainage solutions

- Quick-connect or threaded fittings available to match industrial standards (DIN, SMS, clamp, etc.)

- Full-drain valve: ball or butterfly (up to DN50), ensuring complete emptying with no residue

Additional equipment

- Mechanical or motor-driven agitators – for consistent liquid homogenization

- Integrated CIP (Cleaning-In-Place) systems – for simplified in-place cleaning

- Level indicators – for fast and easy volume monitoring at a glance

|

| Exemple de dôme adapté aux agitateurs |

Thanks to its modular options, the palletizable stainless steel tank becomes a fully tailored solution — ideal for professionals in the food, chemical, pharmaceutical, and cosmetics industries.

which industries are palletized stainless steel tanks best suited for ?

Arsilac’s palletized stainless steel tanks are engineered to meet the operational and regulatory needs of a wide range of industrial sectors. With their mobility, corrosion resistance, flawless hygiene, and customization options, they are perfectly suited for any environment where liquids or semi-liquids require frequent handling.

Food & beverage industry

In the food sector, compliance with strict hygiene regulations (HACCP, EU 1935/2004, FDA) is critical.

Mobile stainless steel tanks are ideal for temporary storage, liquid transfer, or fermentation in food processing facilities.

Typical applications :

- Storage of fruit juice, syrups, milk, or oils

- Preparation of sauces, creams, purées

- Transfer of liquid products between production stages

Key advantages :

- AISI 304/316 stainless steel certified for food contact

- Easy mobility within production areas

- CIP-ready for simplified in-place cleaning

Chemical industry

In chemical manufacturing, palletized stainless steel tanks are valued for their corrosion resistance, leak-proof construction, and versatility. They allow safe transport of corrosive or sensitive liquids across production zones.

Typical applications :

- Storage of solvents, acids, and bases

- Transfer of liquid formulations

- Buffer tanks for filling lines

Useful options :

- AISI 316 stainless steel for aggressive environments

- Leak-tight valves, thermal insulation

- Level indicators for precise dosing

Cosmetics & pharmaceutical industry

In cosmetics and pharmaceuticals, traceability, hygiene, and process precision are non-negotiable. Mobile stainless steel tanks ensure smooth transport of preparations while maintaining strict cleanliness and safety standards.

Common uses :

- Storage of liquid ingredients (glycerin, essential oils)

- Preparation of creams, gels, and lotions

- Mixing of sensitive active ingredients

Key features :

- Smooth BA-finish interior for easy cleaning and disinfection

- Option for integrated agitator to ensure product homogeneity

- Airtight lids to protect contents

ordering and delivery across europe

The palletized stainless steel tanks featured in the Arsilac catalog are available exclusively by order, ensuring a solution that’s fully tailored to your industrial requirements. With a proven logistics network, each tank is delivered across Europe quickly and reliably.

Made-to-order manufacturing for precision equipment

Every tank is built according to your selected technical specifications: capacity, steel grade, drainage system, lid type, agitation options, thermal accessories, and more.

This custom approach meets the demands of even the most complex industrial environments — while guaranteeing consistent, high-quality results.

A dedicated technical advisor is available to support each client in selecting the right model, customizing options, or designing a fully tailored solution.

Fast, secure european delivery

Thanks to a network of trusted logistics partners, Arsilac ensures safe and efficient delivery throughout :

- Mainland France and overseas territories (DOM-TOM)

- Belgium, Luxembourg, Switzerland

- Spain, Italy, Germany, Austria

- Netherlands, Portugal, Poland, and other EU countries

Robust, hygienic, and fully customizable, Arsilac’s palletized stainless steel tanks are a logistical and technical reference for the storage and handling of liquids in demanding industrial settings. Their palletized base allows seamless integration into production lines — simplifying safe transport, fast cleaning, and efficient liquid processing. Available in volumes from 500 to 2,000 liters, they suit a wide range of applications, from food processing to chemicals and cosmetics. Custom-built, delivered across Europe, and fully configurable to your needs — these tanks meet the highest standards of industrial performance.

✖ Unsure if your project is feasible ?

Investing in high-quality stainless steel tanks is a smart step toward successful production and customer satisfaction. Don’t hesitate to contact an Arsilac advisor for expert guidance or to learn more about the stainless steel tank models best suited to your industrial needs.

faq – quality of industrial stainless steel tanks

- What’s the difference between a palletized stainless steel tank and a standard tank ?

A palletized stainless steel tank features a base designed for easy handling by forklift or pallet jack, making internal site transport much easier. Unlike a fixed or leg-mounted tank, it offers enhanced mobility without the need for lifting equipment. It's ideal for workshops, production lines, or labs that require secure, transportable containers.. - Can a palletizable stainless steel tank be used in food processing environments ?

Yes. The palletizable tanks we offer are made from AISI 304 stainless steel (or AISI 316 upon request), both suitable for food-grade applications. Their smooth BA-finish interiors and TIG-passivated welds ensure a high level of hygiene and easy cleaning — fully compliant with HACCP and EU 1935/2004 standards. - Can the accessories on mobile stainless steel tanks be customized ?

Absolutely. Tanks can be fully customized to fit your process, including : Lid types (lever-lock, floating, semi-open) ; Integrated agitators ; Level indicators ; CIP systems ; Thermal insulation. You can also select from threaded, quick-connect, or custom fittings based on your operational needs. - What is the average manufacturing and delivery time ?

Lead times depend on the model, capacity, and selected options. On average, made-to-order manufacturing takes 2 to 6 weeks, plus shipping time depending on destination. An advisor can provide a precise estimate once your project is validated.

#stainlesssteeltank #mobiletank #palletizedtank #industrialtank #foodindustry #chemicalprocessing #pharmaceutical

_

Note : This FAQ is for informational purposes only and does not constitute professional advice. Please consult industry experts and ensure compliance with applicable regulations.