Discover how to professionally brew a beer

Following the brewing training of Edouard Bonnet last September at Lycée Biotech Douai / Wagnonville, discover the stages of making beer with the help of Stéphane Hourdquin, manager of the Braserie La BarB in Thiant near Valenciennes.

1 - Crushing

Crushing is to burst the malt bark to get a milling that will allow for good enzyme reaction and sugar formation during baking. Good crush means good must. The important part of this step is to find the best grind thickness. Too thin, particles will be more efficiently converted by enzymes but the result of overly crushed nuclei will produce some kind of flour. On the contrary, too thick, particles will be easily filtered but will struggle to be converted by enzymes. So good grinding is a range of particle sizes that allows the best compromise between extraction and filtration.

|

2 - The punching

Pooring helps to extract sugars from cereal when contacting hot water. This process is carried out in a material tank, a cylindrical container where malted cereal and hot water are mixed with a mechanical device.

|

|

|

|

At the end of this process, the result obtained in the form of juice is called the must and will be transferred to the boiling tank. Solid waste is called 'dr êcheche', emptied from tanks, it is very often recycled to feed livestock.

|

|

3 - The boil

Appears the hops step of adding hops. With the mixture brought to a boil, it promotes the appearance of bitter flavors. This bitterness comes from a yellowish resin produced by hops.

When cooking the must, the boil focuses on destroying the enzymes whose role is now complete. This is also when we witness the breakage stage: the coagulation of the proteins held in the tank. Finally, the sterilized must and the presence of hops have eliminated all forms of bacteria and other microorganisms, whether pathogenic or not.

4 - Fermentation

The juice from the boil tank is then transferred to a fermenter by passing through filters twice. First one is a hops square filter. The second a plate filter to reduce the temperature from 100° to 20°C. Once the transfer is done, yeasts are added so the fermentation begins.

|

|

|

|

|

Discover the cylindrical conical tanks of all capacity available in stock.

|

|

5 - Nettoyage avec CIP

Le "cleaning-in-place" fait référence aux méthodes utilisées pour nettoyer les surfaces intérieures des tuyaux, des réservoirs et des cuves de brassage sans démontage et nettoyage des pièces individuellement à la main. Un nettoyage fréquent de ces équipements est nécessaire pour maintenir la qualité microbiologique et chimique de la bière produite. La désinfection de l'équipement de brassage doivent avoir lieu de manière à permettre à l'équipement de rester fermer et à maintenir le personnel en sécurité des solutions de nettoyage chimiques souvent très chaudes

|

|

6 - The Guard

Once the fermentation is over, the young beer needs to be refined to allow for full flavour to flourish. She is then housed in guard tanks for optimal ripening. This step makes the beer ripen and refine.

|

Laissons là se reposer, car prochainement, la suite des procédés de fabrication avec les étapes de la refermentation, le resucrage et l'embouteillage.

#arsilac #brasserie #labarb #innovation #biere #brasseur #beer #brewery #craftbeer #beerlovers #brasserie #brouwerij #bier #brewingequipment #beerequipment #biereartisanale #craftbeer

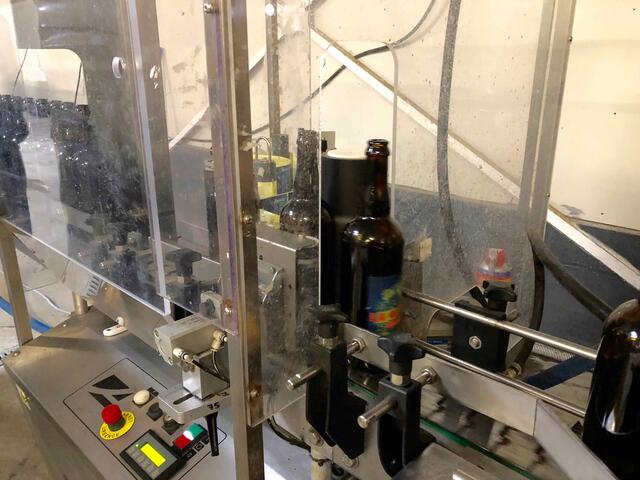

7 - beer bottling

And finally, after resting for a while, the hops juice is ready to be conditioned, it's traffic jam time. Once the containers are received, the containers navigate a complete bottling line. Starting with labelling, to fill and end with encapsulation.

|

|

|

|

|

|

|

Check out the bottling equipment available in stock.

|

|

|

TADAM ! It's just to taste ! ;)

#arsilac #brasserie #labarb #innovation #biere #brasseur #beer #brewery #craftbeer #beerlovers #brasserie #brouwerij #bier #brewingequipment #beerequipment #biereartisanale #craftbeer