Durability and performance of industrial tanks

Stainless steel finishes and the advantages of bright annealing

In an industrial landscape driven by continuous improvement, selecting the right stainless steel finish is a strategic decision. While all stainless steels are valued for their corrosion resistance and ease of cleaning, surface finishes can significantly impact their mechanical performance, appearance, chemical resistance—and compliance with hygiene or safety standards. Among the options available for stainless steel tanks, bright annealing stands out for its superior mechanical properties and long-term durability.

In this article, discover why this finish is a smart investment for professionals in the food and beverage, chemical, pharmaceutical, and liquid processing industries.

Understanding stainless steel surface finishes

Choosing the right surface finish is essential to ensure the material performs at its best

The Role of Surface Finish in Stainless Steel

Surface finish plays a critical role when selecting stainless steel, regardless of its intended use. For decorative applications, the finish affects visual appeal and becomes a key part of the design specification. For non-decorative uses, it impacts friction, wear, maintenance, and corrosion resistance. That’s why selecting the appropriate finish—and clearly defining it—is so important.

Categories of Surface Finishes

There is a wide range of standard and special surface finishes available for stainless steel. These are generally grouped into three main categories:

- Mill finishes

- Raw finishes

- Special finishes

Each category has a standard designation or commonly used name. Some finishes are known by more than one term, which can lead to confusion.

Mill finishes—whether for hot-rolled or cold-rolled products—form the basis of stainless steel flat product surfaces. In addition to being widely used for standard components, they also serve as a starting point for special finishes designed for industrial applications.

Types of Finishes

Four surface finishes are particularly important in construction and architecture: 1D, 2D, 2B, and 2R.

To optimize corrosion resistance upon delivery, these factory finishes undergo pickling after hot rolling and annealing.

- 1D

This finish results from final hot rolling, followed by annealing and pickling. It has a dull, slightly rough appearance with low reflectivity. Commonly used for thick sheets and plates, it was originally intended for non-decorative applications where surface appearance is not a priority — such as structural parts and support elements. - 2D

After final cold rolling, the material is annealed and pickled. It has a matte finish with low reflectivity. This finish suits industrial and architectural applications where visual appeal is secondary. Relatively prone to fingerprint marks. - 2B

Similar to 2D up to the final stage, 2B finishes undergo an additional light cold rolling pass using highly polished rollers. This creates slight surface work hardening and a brighter appearance. Today, it is the most widely used surface finish and often serves as the base for brushed and polished finishes. Still somewhat sensitive to fingerprinting. - 2R

After cold rolling, the material is annealed in a controlled atmosphere to achieve an exceptionally smooth surface. A skin-pass (or temper mill) operation ensures flatness, mechanical properties, and surface finish (roughness, brightness, etc.). This ultra-smooth finish reduces the build-up of airborne contaminants and moisture more effectively than other finishes — and it also facilitates cleaning.

| Finish | Description | Process | Appearance | Typical application |

|---|---|---|---|---|

| 1D | Hot rolled, annealed and pickled | No cold rolling | Dull, rough | Heavy industry, structural components |

| 2D | Cold rolled, annealed, pickled | Cost-effective finish | Light grey, slightly smooth | Industrial casings, internal components |

| 2B | Cold rolled, annealed, skin-passed | Smoother surface than 2D | Slightly reflective | Tanks, sheets, food processing equipment |

| 2R (BA) | Bright Annealed | Inert atmosphere annealing | Very smooth, bright, oxidation-free | Food-grade tanks, pharmaceutical and cosmetic use |

| Mirror finish | Mechanically or electrolytically polished | Polishing treatment | Perfect mirror finish | Medical industry, high-end design |

|

|

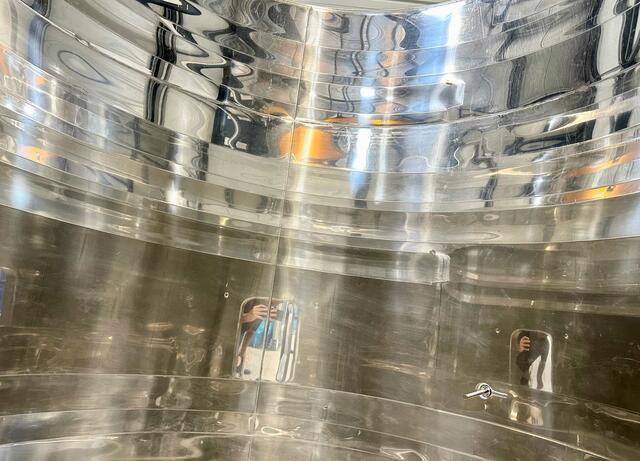

Properties of bright annealed stainless steel finish

Bright annealing is a heat treatment process carried out in a controlled atmosphere, often combined with light skin-pass rolling. This method enhances the mechanical properties and structural stability of stainless steel (typically 304L or 316L). Bright-annealed 304L steel undergoes treatment in an oxygen-free furnace, producing an exceptionally smooth surface. The addition of skin-pass rolling gives it a subtle sheen — slightly dulled from a distance — similar to that of an aged mirror, though less reflective than mirror-polished stainless steel. This ultra-smooth surface is easy to clean.

Finish 2R = Bright Annealed

Also derived from cold rolling and pickling, this finish includes a final annealing stage in a controlled-atmosphere furnace. The absence of oxygen results in a reflective appearance. Its high flatness makes it an ideal base for additional treatments such as mirror polishing or chrome plating.

Cold rolling of the material, followed by softening and pickling, produces a smoother, less abrasive surface.

Main benefits of bright annealing :

- Definition : A smooth, easy-to-clean surface prevents the buildup of dirt, bacteria, and other contaminants.

- Effect of Rolling : The reduced surface roughness limits contamination points, making cleaning and disinfection more efficient.

- Applications : Essential in industries where hygiene is critical — such as food and beverage processing, pharmaceuticals, and cosmetics.

Increased Ductility: Stainless Steel That Withstands Deformation

Bright annealing makes stainless steel more malleable and less prone to mechanical deformation. This property is essential for tanks exposed to pressure fluctuations, thermal cycles, or repeated handling.

⮕ Benefit : Reduces the risk of cracking or long-term failure.

Elimination of Internal Stress: Guaranteed Structural Stability

Manufacturing processes like bending, welding, or rolling often leave residual stress in the metal. Bright annealing relieves these stresses, ensuring a stable shape and consistent mechanical strength.

⮕ Benefit : Tanks maintain their form over time, even under heavy-duty use.

Uniform Microstructure: A Strong, Reliable Foundation

By reorganizing the metal grain structure, bright annealing creates a homogeneous internal matrix, minimizing weak spots and improving resistance to mechanical fatigue.

⮕ Benefit : Enhanced durability against vibration, impact, and wear.

Enhanced Corrosion Resistance

The smooth surface achieved through bright annealing promotes the formation of a stable passive layer, shielding the metal from chemical exposure.

⮕ Benefit : Reduced corrosion, even in humid or acidic environments.

Hygiene and cost efficiency

The bright annealed finish of stainless steel offers significant advantages in terms of hygiene and water savings.

Lower Water and Chemical Consumption

- Reduced water usage : Tanks with a bright annealed finish optimize water consumption during cleaning and descaling processes, thanks to low particle adhesion.

- Less chemical use : Smooth surfaces require fewer cleaning agents, reducing the amount of substances entering waste systems.

- Shorter cleaning times : Cleaning is faster, cutting downtime and increasing operational efficiency.

Less Maintenance, More Profitability

Thanks to enhanced mechanical properties, bright annealed stainless steel:

- Extends tank lifespan

- Reduces corrective maintenance

- Improves process reliability

〃Return on investment : Fast payback due to fewer breakdowns and less production downtime.〃

Bright annealing stands out for its technical benefits: it eliminates internal stress, ensures a homogeneous microstructure, provides a smooth, passive surface, and enhances corrosion resistance. These features make it an ideal choice for stainless steel tanks that must meet high standards in durability, cleanability, and mechanical stability. Integrating this finish into your equipment means ensuring consistent performance, reduced maintenance, and long-term compliance with industrial standards.

✖ Unsure if this solution fits your project ?

Don’t hesitate to contact an Arsilac advisor for more information about stainless steel finishes. We’ll help you find the right tank solution for your specific needs.

#stainlesssteel #tank #brightannealing #surfacefinish #corrosionresistance #durability #cleanability

_

Note : This article is for informational purposes only and does not constitute professional advice. We recommend consulting with industry experts and complying with applicable regulations.