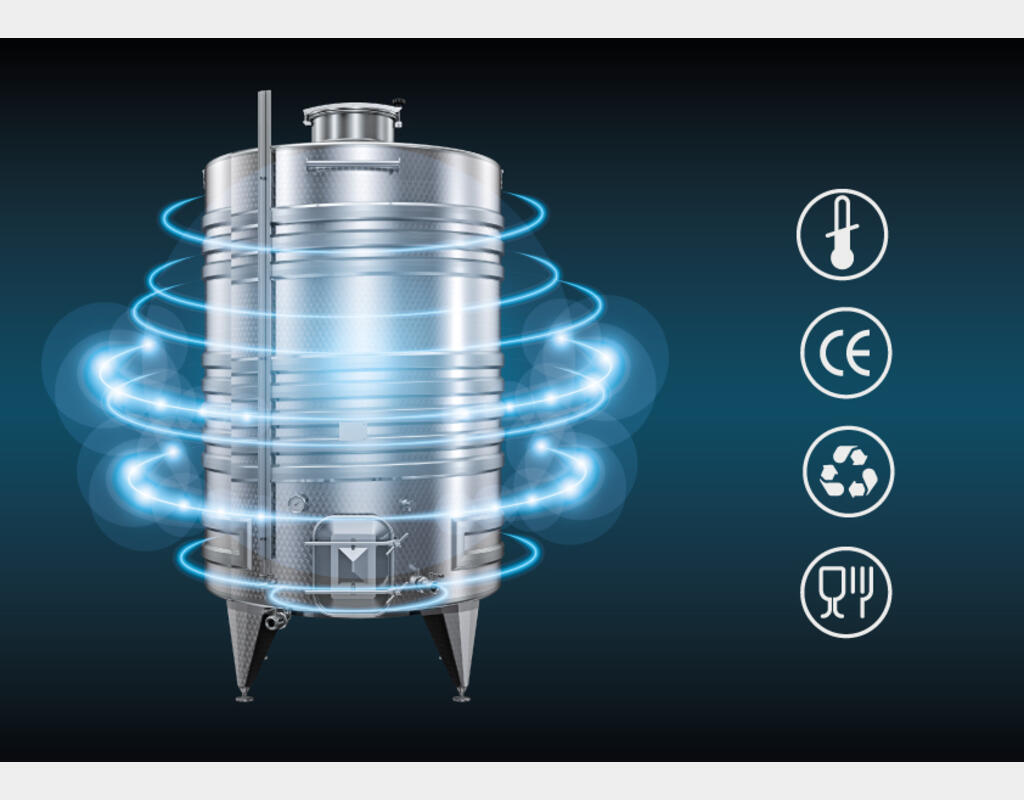

Temperature control : discover the honeycomb system

Stainless steel tanks with integrated cooling systems

Technological innovation has always been a key driver of industrial progress, and in this context, stainless steel tanks equipped with a honeycomb exchange surface represent a significant advance. These systems, combining durability and efficiency, mark a turning point in the fields of conservation, storage and processing in various industries.

→ To find out more about thermoregulation, read our article on coils

the evolution of stainless steel tanks

Historically, stainless steel tanks have been favoured for their corrosion resistance and longevity. Now, with the incorporation of the honeycomb heat exchange surface, these vessels are reaching a new level of performance. This design enables the temperature of the liquid to be precisely maintained, which is essential in applications such as pharmaceutical manufacturing, food fermentation or chemical reaction.

|

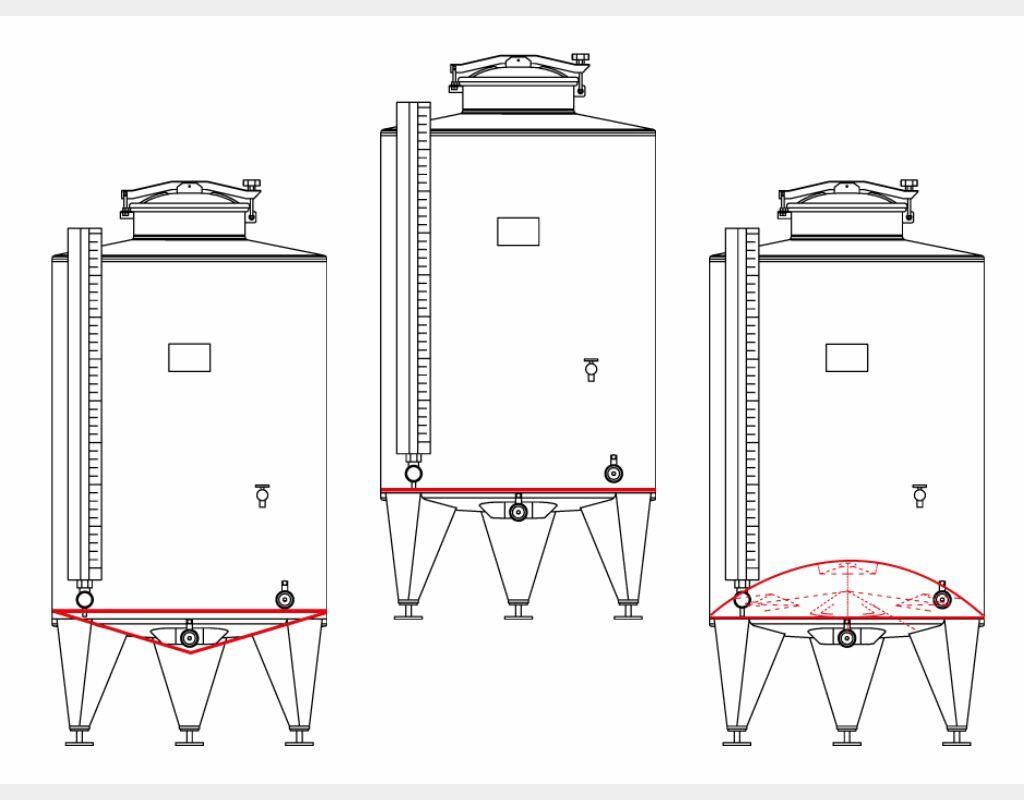

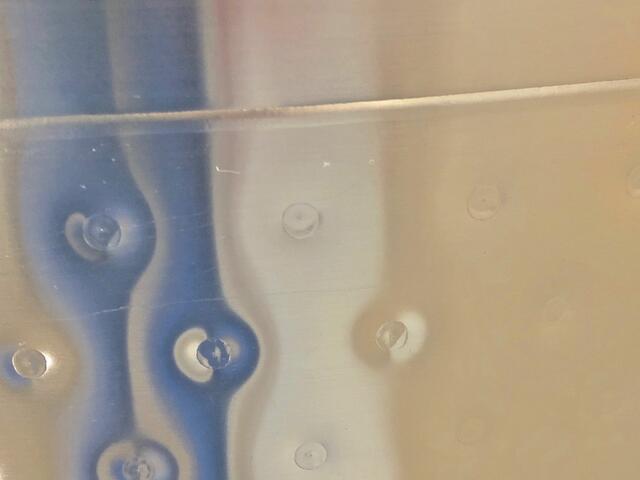

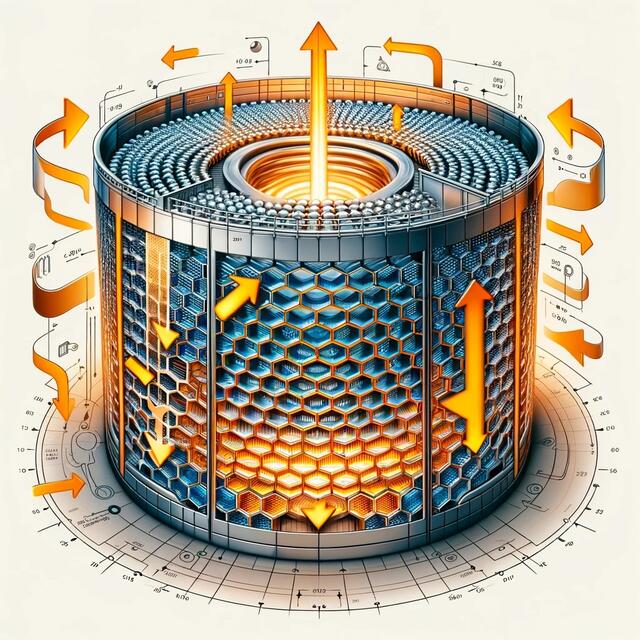

the honeycomb concept: a thermal revolution

The honeycomb heat exchange surface is made up of thin metal strips arranged in the shape of a honeycomb and integrated into the wall of the tank. These channels allow the passage of a heat transfer fluid, generally hot or cold water, to regulate the temperature of the liquid contained in the tank. This configuration provides a large surface area for contact between the fluid in the tank and the coolant, resulting in more efficient heat transfer. This unique configuration facilitates even temperature distribution and improves energy efficiency. The benefits are many: reduced operating costs, improved product quality, and a smaller environmental footprint.

|

diversified industrial applications

These tanks are used in a variety of industries. In the food industry, they are essential for the fermentation of wine and beer, ensuring consistent quality. In the chemical and pharmaceutical industries, they allow precise control of thermal reactions, ensuring safe and efficient processes.

Food industry

Stainless steel tanks with a honeycomb heat exchange surface are used for cooling dairy products such as milk, cream and yoghurt. They are also used for cooling fruit juices, wines and beers.

Chemical industry

Stainless steel tanks with a honeycomb exchange surface are used for cooling acids, bases and other chemicals. They are also used for cooling pharmaceutical products, such as vaccines and medicines.

|

Stainless steel tanks with a honeycomb exchange surface represent a major advance in storage and treatment technology. They symbolise the harmony between innovation, efficiency and sustainability, and will continue to play a crucial role in the evolution of industrial processes.

→ Discover all the temperature-controlled stainless steel tanks available in stock

#tank #thermoregulation #thermal exchange #stainless steel #industry