Used wine bottling machines : Reliable equipment at lower cost

Cappers, rinsers, fillers, corkers & labelers for wine bottling

Investing in a second-hand bottling machine is a cost-effective and reliable alternative to purchasing new equipment. This choice supports the need to reduce capital expenditure, ensures faster availability, and maintains technical reliability in demanding food and beverage environments. This guide outlines the key benefits, types of bottling equipment available, and the selection criteria for making a secure and long-term investment.

why buy a pre-owned bottling machine ?

- Optimized investment : Acquisition costs reduced by up to 60% compared to new.

- Long-lasting reliability : Constructed with 304/316L stainless steel and durable mechanical components.

- Immediate availability : No lead times — machines ready for quick installation.

- Sustainable choice : Refurbished and reconditioned equipment helps lower your environmental footprint.

- Quality assurance : All machines are inspected, tested, and meet safety and operational standards equivalent to new equipment.

|

The Different Types of Wine Bottling Machines

To ensure efficient and professional wine bottling, several types of specialized machines are required. Each plays a crucial role in the final product’s quality and in the overall productivity of the bottling line. In this section, discover the key features of essential equipment — from cappers and rinsers to fillers, corkers, and labelers — and how investing in second-hand machines can meet the needs of a winemaking operation while significantly reducing costs.

Cappers : use and second-hand models

The capper is essential for sealing wine bottles, ensuring an airtight closure and a professional product presentation. Second-hand wine cappers are available in various models, ranging from manual versions to semi-automatic machines — ideal for adapting to different production volumes. Choosing a used capper offers reliable performance while significantly reducing costs, without compromising bottling quality.

Pre-owned models also come with a range of features, allowing you to find the capper that best meets your production requirements. Investing in a used capper helps lower expenses while delivering the same high-quality finish as new equipment.

|

Rinsers : purpose and options for bottle cleaning before filling

Before filling, bottles must be thoroughly cleaned to prevent contamination and ensure wine quality. Used wine bottle rinsers handle this essential cleaning step. These second-hand machines provide cost-effective solutions without compromising efficiency, with models designed for various production types and volumes.

Choosing a used rinser allows you to maintain high hygiene standards — a critical step in wine production. Available options include semi-automatic rinsers, ideal for small to medium-sized operations, ensuring consistent and thorough cleaning with each cycle.

|

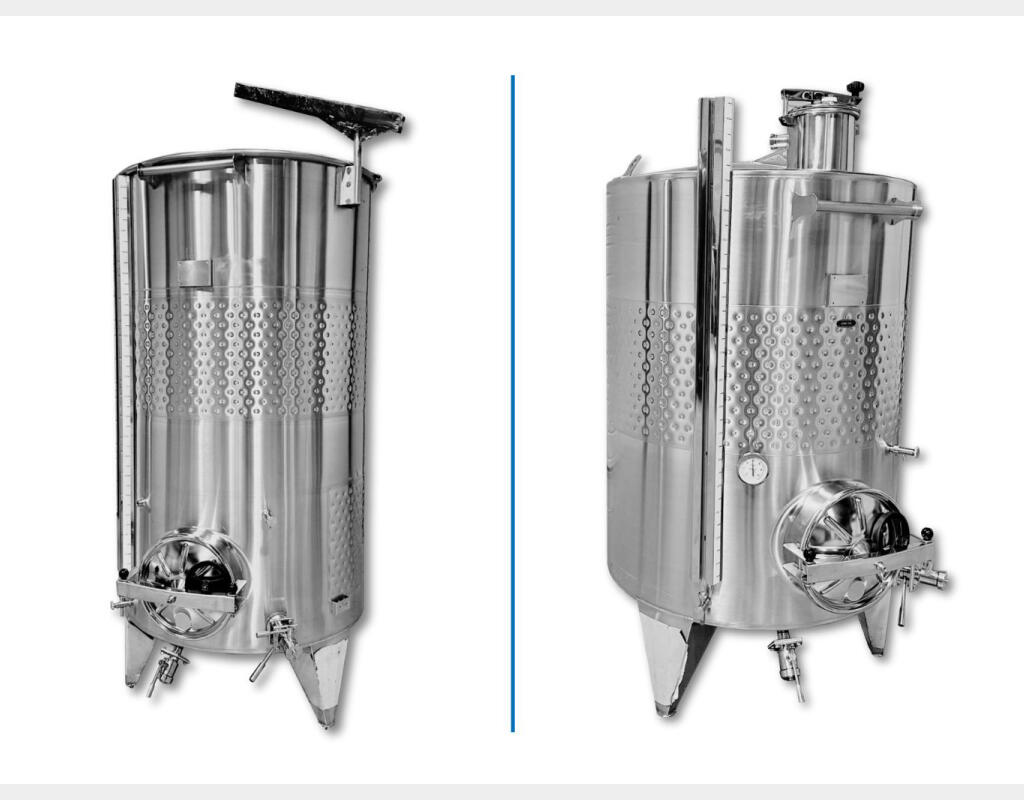

Fillers : operation and second-hand options

The filler plays a central role in the bottling process by ensuring precise filling of bottles without loss or alteration of the wine. Pre-owned wine fillers offer performance comparable to new equipment, at a fraction of the cost. With both semi-automatic and manual options available, producers can tailor the equipment to the specific needs of their winery.

Used fillers allow efficient management of production flow without compromising quality, ensuring consistent and accurate bottling. Whether for high-volume use or smaller-scale operations, second-hand fillers remain a reliable and cost-effective solution.

|

Corkers : description and types of closures

The corker is essential for securely sealing bottles, thereby preserving the wine’s quality and freshness. Second-hand corking machines offer various types of closures to suit different cork specifications (natural cork, synthetic, etc.). By choosing a pre-owned corker, producers gain access to a high-performance and versatile machine while keeping their investment under control.

Used models typically include options for various types of stoppers, providing valuable flexibility for winemakers. As a result, second-hand corkers can meet the requirements of every wine style without the need for a costly investment.

|

Labeling machines : importance and setup of pre-owned labelers

Labeling is the final stage of the bottling line, playing a crucial role in product marketing and brand image. Second-hand labeling machines ensure precise application of labels, providing a clean and professional presentation of the final product. Depending on production needs, semi-automatic and automatic used labelers are available to suit operations of various sizes.

Investing in a used labeler not only helps reduce costs but also maintains a high aesthetic standard for every bottle. Pre-owned models often include adjustable settings to accommodate different label formats, making the equipment versatile and scalable to meet changing production requirements.

|

Buying Second-Hand Wine Bottling Equipment

Purchasing used wine bottling equipment is a strategic decision for many wine producers seeking to balance cost-effectiveness with performance. This choice not only reduces investment costs but also allows for the selection of machines tailored to the specific needs of their winery. In this section, we detail the key criteria for choosing a second-hand bottling line, along with the methods to assess performance and the essential maintenance practices required to ensure the equipment’s longevity.

Selection criteria for a used bottling line

Buying a pre-owned bottling line requires close attention to the condition of critical components such as pumps, valves, and cleaning systems. These elements directly impact the machine’s performance and durability. A thorough inspection can help detect any signs of wear or faults that could affect operation.

A detailed check before purchase is strongly recommended :

- Condition of the frame and motor systems

- Wear of critical components (pumps, seals, filling nozzles)

- Electrical and pneumatic compliance

- Availability of technical documentation

Performance testing : methods to verify machine capacity and efficiency

When investing in second-hand wine bottling machines, it's essential to conduct performance tests to ensure their operational efficiency. These tests help verify whether the equipment meets expected output levels and runs smoothly under various load conditions. Key tests include bottling speed, fill-level accuracy, and cycle consistency.

Prior to purchase, recommended checks include :

- Bottle formats supported (375 ml, 750 ml, magnum)

- Compatibility with cap or cork types

- Output speed in line with production targets

Maintenance considerations : servicing, repairs, and associated costs

A second-hand bottling machine requires regular maintenance to ensure consistent performance and extended lifespan. Maintenance of wine bottling equipment includes periodic checks of components, replacement of worn parts, and thorough cleaning operations. By investing in proactive maintenance, producers can minimize production downtime and maintain the quality of their bottling line.

Before purchasing, it's recommended to anticipate :

- Availability of spare parts

- Estimated annual maintenance costs

- Support for after-sales service and operator training

A selection of pre-owned bottling equipment is regularly updated: complete lines, filling modules, cappers, fillers, and labellers suited for the wine, brewing, and food processing sectors. Each second-hand machine from brands like SIAT, GAI, or SAVOYE is inspected, tested, and refurbished to ensure safe commissioning, full compliance with industrial standards, and professional expectations in terms of productivity, throughput, and packaging quality. Thanks to this reconditioned equipment offer, it becomes possible to reduce capital expenditure, speed up the integration of a used bottling line, and maintain a high level of reliability — all while benefiting from proven technical solutions.

✖ Unsure about the feasibility of your project ?

Don't hesitate to contact an Arsilac advisor if you have any questions or would like more information about the types of equipment used in the industry. Find the bottling solution that best fits your needs.

FAQ - Used Wine Bottling Equipment

How can I check the condition of a used bottling machine ?

A thorough inspection of mechanical parts, motors, and electrical compliance is essential. Prior refurbishment by a specialized supplier is a key safety guarantee.

What standards must be met ?

Bottling equipment must comply with CE requirements, ensure food-grade hygiene, and guarantee operator safety.

What bottling speed should I choose ?

The ideal throughput depends on your production volume : Artisanal wineries: 1,000 to 3,000 bottles/hour, Cooperatives: 5,000 to 10,000 bottles/hour, Industrial scale: Over 10,000 bottles/hour.

Can I assemble a line using different second-hand modules ?

Yes — as long as mechanical compatibility and overall production flow are verified.

#bottling #wineryequipment #corkingmachine #fillingmachine #capsulingmachine #labelling #GAI #SAVOYE #foodindustry #winemaking #industrialinvestment #usedequipment

_

Note : This article is for informational purposes only and does not constitute professional advice. You should consult with industry experts and comply with relevant regulations.