Pressure in tanks

Key concepts for safe and efficient use

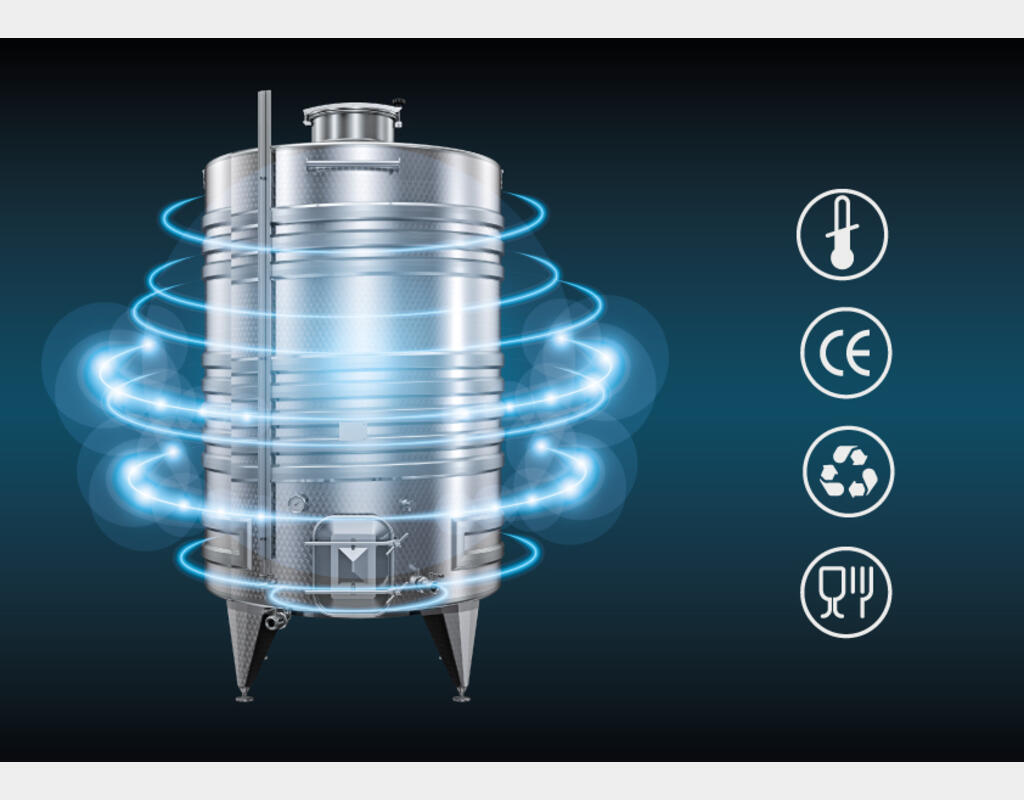

Stainless steel tanks designed to withstand pressures of up to 1 bar play a vital role in industries such as food processing, pharmaceuticals, and chemicals. Understanding how pressure behaves in these tanks is essential to ensure safe and efficient operation. This article outlines the key principles of pressure management in stainless steel tanks, the main factors that influence pressure levels, and essential risk prevention measures.

〃 Low pressure doesn't mean low risk. 〃

What is pressure ?

Pressure is the force exerted by a fluid (liquid or gas) on a given surface. It is generally measured in bars, a unit of pressure equivalent to 100,000 pascals (Pa). One bar represents approximately the average atmospheric pressure at sea level.

Imagine you have a block of modelling clay in your hands. If you press on it with your finger, you are exerting a force on the clay. This force is distributed over the surface area of your finger in contact with the clay. Pressure is defined as the force applied per unit area. In other words, it represents the intensity with which the force is distributed over a surface.

Mathematically, pressure (P) is calculated by dividing the force (F) by the surface area (S) over which it is applied: P = F / S

Pressure units

The most common unit of pressure is the pascal (Pa), which corresponds to a force of one newton (N) applied to an area of one square metre (m²). Other commonly used units of pressure include the bar, pound per square inch (psi) and atmosphere (atm).

Pascal's principle

Pascal's principle states that in an incompressible fluid at static equilibrium, the pressure applied at any point in the fluid is transmitted uniformly in all directions.

This principle has many practical applications, particularly in hydraulic systems and presses. For example, a hydraulic cylinder uses a piston to amplify a force applied to a small piston, enabling heavy loads to be lifted.

In summary, pressure is a fundamental concept in physics that quantifies the intensity of a force distributed over a surface. Pascal's principle plays an important role in understanding the behaviour of fluids and has many practical applications.

Importance of Pressure

Pressure plays a crucial role in various industrial and food processes :

- Maintaining product integrity: Pressure can protect the product from oxidation, microbial contamination and other alterations.

- Controlling chemical reactions: In the pharmaceutical and chemical industries, pressure is used to control chemical reactions.

- Product transfer: Pressure facilitates the transfer of liquid or paste-like products in production systems.

Factors affecting pressure

Several factors affect a vessel's ability to withstand high pressure, including :

- The thickness of the vessel walls

The thicker the walls, the more pressure the vessel can withstand without risk of deformation or cracking. - The construction material

Stainless steel is a strong and durable material that can withstand high pressures without corroding or degrading quickly. - The design of the tank

The shape and structure of the tank, including reinforcements and supports, play an important role in its ability to withstand pressure. - Operating temperatures

High temperatures can affect the strength of materials and must be taken into account when designing vessels. - Nature of the content

Denser fluids, such as water, generate greater pressure than lighter fluids, such as air. - Tank volume

A smaller volume tank will experience higher pressure to contain the same amount of fluid as a larger tank. - Inert gases

The injection of inert gases, such as nitrogen, can increase the pressure inside the tank.

When a tank is filled with a pressurised fluid, the fluid exerts a force that is evenly distributed across all of the tank's internal surfaces. This pressure can be calculated using specific formulas that take into account the weight of the fluid, the height of the fluid column and atmospheric pressure.

Safety devices, such as pressure relief valves, are generally installed on tanks to prevent dangerous overpressure. In addition, regular inspections and tests are carried out to ensure that stainless steel tanks remain compliant with current safety standards.

Risks associated with incorrect pressure calculationS

There are numerous risks associated with incorrect calculations of the pressures supported by low atmospheric pressure stainless steel tanks (maximum 1 bar), which can have serious consequences for safety, the integrity of installations, and compliance with standards and regulations.

Risk of bursting or rupture

If the internal pressure of a tank exceeds the resistance capacity of its walls due to an incorrect calculation, there is a risk of bursting or rupture. This can result in :

- Injury or death: Metal fragments and the contents of the tank can seriously injure or kill operators and personnel in the vicinity.

- Property damage: Surrounding equipment and facilities may be severely damaged.

- Production stoppage: Interruption of operations to repair or replace the defective tank may result in significant financial losses.

Risk of leakage

Incorrect pressure calculations can cause partial failures, such as cracks or welds breaking, leading to leaks. The consequences include :

- Contamination : In the food, pharmaceutical or chemical industries, leaks can contaminate products and affect quality.

- Environmental risks : Leaks of hazardous substances can pollute the environment, requiring costly and complex decontamination measures.

- Product loss : Leaks of expensive products can result in significant economic losses.

Accelerated corrosio

Incorrect pressure calculations can lead to undersized walls, increasing mechanical stress and promoting corrosion, especially if the tank is in contact with corrosive substances. This can :

- Reduce the tank's service life : Premature wear and tear on the tank will result in additional maintenance or replacement costs.

- Compromise structural integrity : Corrosion can weaken the structure of the vessel, increasing the risk of leaks or rupture.

Compliance and regulations

Tanks must comply with safety and manufacturing standards (such as ASME, EN). Incorrect pressure calculations can result in :

- Regulatory non-compliance: Non-compliant tanks may be banned from use, resulting in fines and penalties.

- Legal liability: In the event of an accident, the company may be held liable and face legal action and insurance claims.

Fatigue and pressure cycles

If the vessel is subjected to frequent pressure variations (even less than 1 bar), an incorrect calculation may not take into account the effects of material fatigue. This can cause :

- Microcracks : Fatigue can lead to the formation of microcracks which, over time, develop and compromise the integrity of the vessel.

- Premature failure: The accumulation of fatigue damage can lead to premature and unexpected failure of the tank.

Poor accessory design

Auxiliary equipment (safety valves, pressure gauges, etc.) may be incorrectly specified if the pressure is miscalculated, which can result in :

- Incorrect triggering: Incorrectly calibrated safety valves may not open in time, increasing the risk of explosion.

- Incorrect instrument readings: Incorrect pressure gauges may provide false readings, misleading operators.

Long-term risks

In addition to these immediate risks, miscalculating pressure can also have long-term consequences, such as :

- Increased maintenance costs: Tanks subjected to excessive pressure are more likely to fail and require more frequent repairs or replacement.

- Reduced tank life: Tanks subjected to excessive pressure have a shorter service life.

- Increased risk of accidents: Poorly maintained tanks or tanks with a reduced service life are more likely to cause accidents.

It is therefore essential to ensure that low atmospheric pressure stainless steel tanks are designed and used in accordance with current safety standards.

Preventive Measures

To avoid these risks, it is crucial to :

- Design and manufacture in accordance with current standards: Tanks must be designed and manufactured in accordance with standards and regulations applicable to the food industry, such as ASME, PED or FDA (Food and Drug Administration) requirements. The thickness of the walls, the choice of materials and the manufacturing techniques must be adapted to withstand the maximum pressures expected, with an appropriate safety margin.

- Installation of safety devices: Pressure relief valves must be installed to prevent dangerous overpressure beyond the design limit of the tanks. Pressure gauges and alarm systems are used to continuously monitor internal pressure and alert personnel in the event of a deviation.

- Perform accurate calculations : Use validated methods and tools for calculating pressures and stresses.

- Comply with standards : Ensure that all designs and manufacturing processes comply with international standards.

- Regular inspection : Carry out regular inspections and maintenance to detect and correct any signs of weakness.

- Continuous training : Train personnel in best practices for design, maintenance and safety.

Calculating the permissible pressure of a stainless steel tank

To calculate the permissible pressure of a stainless steel tank, it is important to follow a series of key principles that take various factors into account. Here is an explanation of the process :

Understanding the properties of bursting or rupture material

- Type of stainless steel : Different types of stainless steel (such as 304 or 316) have different mechanical properties, including tensile strength and yield strength.

- Properties at operating temperature: The mechanical properties of stainless steel change with temperature. It is crucial to use the values appropriate for the operating temperature of the vessel.

Determining wall thickness

- Nominal thickness : This is the specified or measured thickness of the vessel wall.

- Safety margins: Include margins for manufacturing tolerances and possible corrosion.

Tank geometry analysis

- Tank shape : The geometry of the tank (cylindrical, spherical, conical, etc.) affects stress distribution and pressure calculation formulas.

- Dimensions : Dimensions such as tank diameter and height directly influence calculations.

Service conditions

- Service pressure : The pressure at which the tank is expected to operate.

- Service temperature: The temperature at which the tank will operate, influencing the properties of the material.

- Type of product stored: The nature of the product (corrosive, toxic, etc.) can affect design choices, particularly with regard to corrosion and chemical compatibility.

Understanding pressure in stainless steel tanks is essential for the safe and effective use of this equipment. By adopting proactive pressure risk management, users can ensure a safe working environment and prevent accidents. Careful selection of tanks, rigorous procedures, adequate training, regular maintenance and appropriate safety systems are essential to minimise risks and maximise safety in industrial processes.

✖ Do you have doubts about the feasibility of your project ?

Please do not hesitate to contact an Arsilac representative if you have any questions or would like more information about the type of pressure supported. Find the tank solution that meets your needs.

#stainlesssteeltank #pressure #safety #industry #riskprevention

_

Note : This article is for informational purposes only and does not constitute professional advice. It is recommended that you consult with experts and comply with the specific regulations of each industry.