From vineyards to energy: equipment recovery

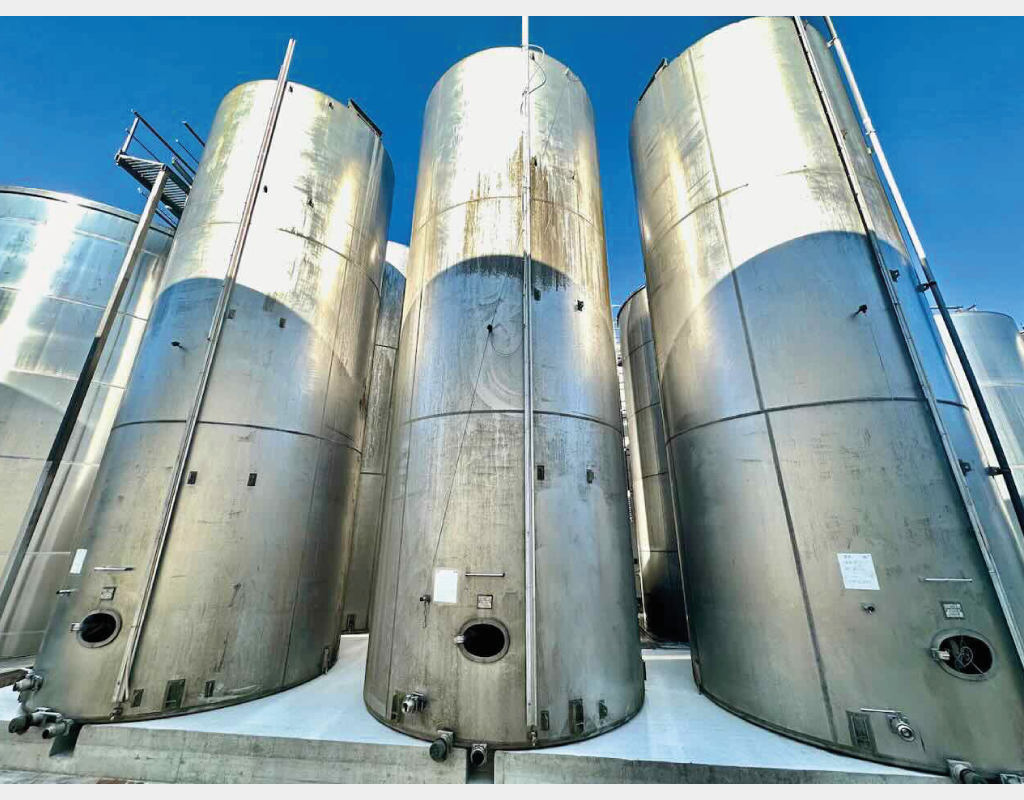

Transfer of two 70,000 l stainless steel tanks for biogas production

Two large-capacity stainless steel tanks were recently relocated from a winery in the Bordeaux region to a biogas production unit. This operation highlights both the logistical efficiency of Arsilac's partners and the relevance of industrial reuse in renewable energy projects.

💡 Using a specialized transporter ensures safe handling and full compliance with current regulations.

A Reuse Project Supporting the Energy Transition

This initiative involves two 70,000 L stainless steel tanks originally used in the winemaking industry. Acquired by Arsilac and repurposed for a biogas production project, these units contribute to the reuse of existing infrastructure and help reduce the environmental footprint of industrial facilities.

The Company MÉTHÉLEC, Recipient of the Tanks, is Developing an Agricultural Methanization Unit for Green Energy Production The choice of refurbished stainless steel tanks allows for a combination of performance, durability, and controlled investment costs, while fully meeting the technical requirements of the sector—such as airtightness, chemical resistance, and long service life.

coordinated logistical and technical expertise

The loading and transport of the two tanks were carried out by Trans’cuves, a subsidiary of the Transports Martin group, specializing in the handling and special transport of tanks and reservoirs. Each unit—measuring approximately 3.5 meters in diameter and over 8 meters in height—required meticulous planning, including securing, bracing, route authorization, escort coordination, and on-site unloading.

This Operation, Carried Out from the Maison Bouey Site (near Créon, Gironde), Reflects the Precision of Coordination Between Stakeholders and Arsilac’s Ability to Support Complex Industrial Projects. Thanks to a tightly managed schedule and collaboration with specialized partners, Arsilac successfully facilitated the transition of the equipment, demonstrating its expertise in handling projects with high logistical demands.

70,000 l stainless steel tanks: a versatile format for industrial storage

With a total volume of 70,000 liters (700 hL), these stainless steel tanks offer an ideal solution for storing substrates, digestate, or effluents in biomethanation processes.

Their intermediate size strikes the perfect balance between storage capacity, footprint, and on-site integration flexibility—making them particularly suited for both new and existing installations.

|

|

The stainless steel models reconditioned by Arsilac undergo a comprehensive quality check :

- Inspection of welds and tank walls

- Verification of fittings, hatches, and valves

- Optional adaptation of accessories to match final use (storage, buffer tank, process feed)

These procedures ensure that each unit is reliable and safe for reintegration into a new industrial cycle.

⭢ 2 stainless steel tanks – 70,000 liters – Reference 007494

Reuse, Performance & Circular Economy

By prioritizing the reuse of stainless steel industrial equipment, project developers significantly reduce lead times and minimize the carbon footprint associated with the production of new tanks. This circular approach aligns fully with Arsilac’s commitment to sustainability and technical optimization. Each transfer becomes a concrete example of circular economy applied to industry—where the performance of pre-owned equipment supports new sectors such as energy, food processing, recycling, or chemicals.

Learn more in the dedicated article on circular economy.

⭢ How can you reduce your carbon footprint with second-hand equipment?

The transfer of two 70,000-liter stainless steel tanks highlights the synergy between technical expertise, logistical performance, and environmental responsibility. Arsilac reinforces its position as a trusted partner in industrial reuse and the repurposing of stainless steel equipment—supporting efficient and sustainable production systems.

✖ Unsure about the feasibility of your project ?

Arsilac supports businesses in the selection, reconditioning, and logistics of stainless steel tanks—both new and pre-owned. If you have any questions or would like more information about the logistics involved in tank transfers, don’t hesitate to contact an Arsilac representative. Let us help you find the installation solution best suited to your operational needs.

#tank #usedequipment #reuse #upcycling #methanation #biomethane #circulareconomy

_

Note : This article is for informational purposes only and does not constitute professional advice. Please consult qualified experts and comply with regulations specific to your industry..