304 or 316L stainless steel tanks: how to choose ?

Differences, uses and industrial choices

Stainless steel is an essential choice in many industries, but how do you choose between 304 and 316L stainless steel? These two alloys are commonly used for tanks, pipes and industrial equipment. In this article, we will compare their compositions, advantages and uses to help you make the right choice.

|

Fundamental differences between 304 and 316L stainless steel

When selecting a material for critical applications requiring corrosion resistance, 304 and 316L stainless steels are generally considered the best options. However, it is important to understand the fundamental differences between these two types of stainless steel in order to make the most appropriate choice for your specific application in your production process.

Chemical composition

For 304, the steel contains approximately 18% chromium and 8% nickel. It is considered a generally usable stainless steel and is widely used in food and domestic applications. It is also highly resistant to internal corrosion caused by acidic foods and beverages, making it a popular choice for piping and storage vessels.

As for 316L, it contains approximately 16% chromium, 10% nickel and 2% molybdenum. The latter element is added to improve corrosion resistance in high-temperature conditions and in environments containing chlorides, such as applications in the chemical and wastewater treatment industries. Due to its superior chemical composition, 316L stainless steel is considered to be more corrosion resistant than 304 stainless steel.

✅ 304 stainless steel : contains approximately 18% chromium and 8% nickel. It is ideal for general and food applications.

✅ 316L stainless steel : contains 16% chromium, 10% nickel and 2% molybdenum. The latter improves corrosion resistance in aggressive environments (salt water, chemicals).

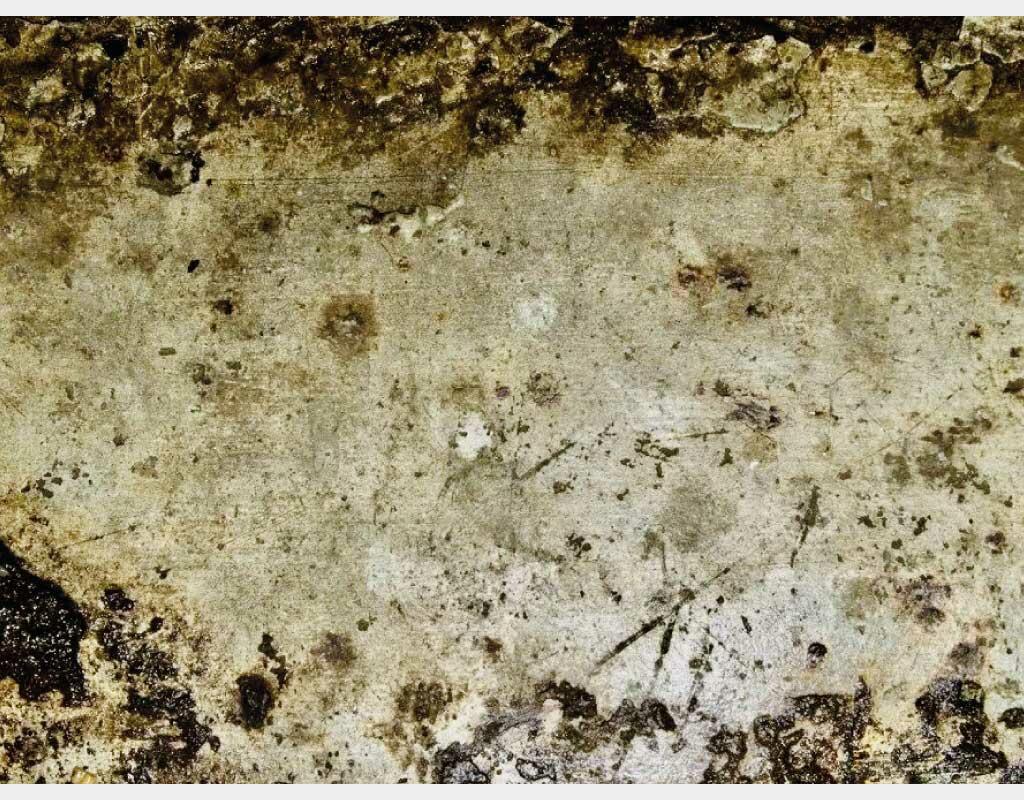

Corrosion resistance

316L and 304 stainless steel are the two most commonly used alloys in industrial applications such as piping, water treatment equipment, and storage or fermentation tanks. Both are considered austenitic stainless steels, meaning they have a stable crystal structure at high temperatures. However, there are crucial differences between these two alloys that can affect their performance in specific applications.

In conclusion, the choice between 304 and 316L stainless steel will depend on the level of corrosion resistance required for a particular application and the environmental conditions to which the steel will be exposed. If minimal corrosion resistance is sufficient, 304 stainless steel may be an economical choice. However, if increased corrosion resistance is required, 316L stainless steel is the most appropriate choice.

🔹 316L stainless steel is more corrosion resistant than 304, particularly in the presence of chlorides and acids.

🔹 304 stainless steel remains an excellent choice for food and domestic use.

|

The special features of 304 and 316L stainless steel for tanks

Stainless steel tanks are a key component in many industrial applications, particularly in food production, pharmaceuticals and beverages. With different types of stainless steel available on the market, it is important to understand the advantages and limitations of each option in order to determine the best solution for your business.

Stainless steel tanks are valued for their durability, corrosion resistance and ease of maintenance. They are often used in harsh environments, such as acidic, alkaline and saline environments, where metal tanks can be damaged quickly. Stainless steel tanks are also easy to clean and disinfect, making them ideal for food and pharmaceutical applications.

There are different types of stainless steel available on the market, such as 304, 316 and 316L stainless steel. 304 stainless steel is the most commonly used and is economical. However, it is less corrosion resistant than other types of stainless steel, which may limit its use in certain applications. 316 and 316L stainless steel are more expensive than 304 stainless steel, but are more corrosion resistant and can therefore be used in more demanding applications.

In conclusion, stainless steel tanks are a popular choice for many industrial applications due to their durability, corrosion resistance and ease of maintenance. It is important to understand the different types of stainless steel available and choose the one that best suits your needs based on corrosion, cost and intended use.

| Criterion | 304 s. steel | 316L s. steel |

|---|---|---|

| Corrosion resistance | Good | Excellent |

| Chloride resistance | Average | Very high |

| Saline environments | ❌ | ✅ |

| Chemical applications | Not very suitable | Recommended |

| Cost | More economical | Higher |

| Standard tank applications | ✅ | ✅ |

💡 Tip : If your application does not involve exposure to corrosive substances, 304 stainless steel is more economical.

|

To make the right choice

- Analyse the environment

Presence of chemicals, humidity, temperature. - Consider durability

If you want a long-term investment, 316L stainless steel is preferable. - Weigh up the cost

316L stainless steel is more expensive but offers better resistance.

✖ Still unsure whether your project is feasible ?

Investing in high-quality stainless steel winery equipment means contributing to the success of your production—and the satisfaction of your customers. Feel free to contact an Arsilac representative for more information or to explore the stainless steel tank models best suited to your needs.

FAQ

What is the difference between 304 and 316L stainless steel ?

The main difference is the presence of molybdenum in 316L stainless steel, which improves its corrosion resistance, particularly in chlorinated environments.

Is 316L stainless steel mandatory in the food industry ?

No, 304 stainless steel is often sufficient. 316L is recommended when conditions are more aggressive or when standards require it.

Why is 316L stainless steel more expensive ?

Because of its enriched composition and superior performance in terms of durability and chemical resistance.

#stainlesssteel #stainlesssteeltank #stainlesssteel304 #stainlesssteel316 #stainlesssteeltank #stainlesssteel

_

Note : This article is for informational purposes only and does not constitute professional advice. It is recommended that you consult with experts and comply with the specific regulations of each industry.