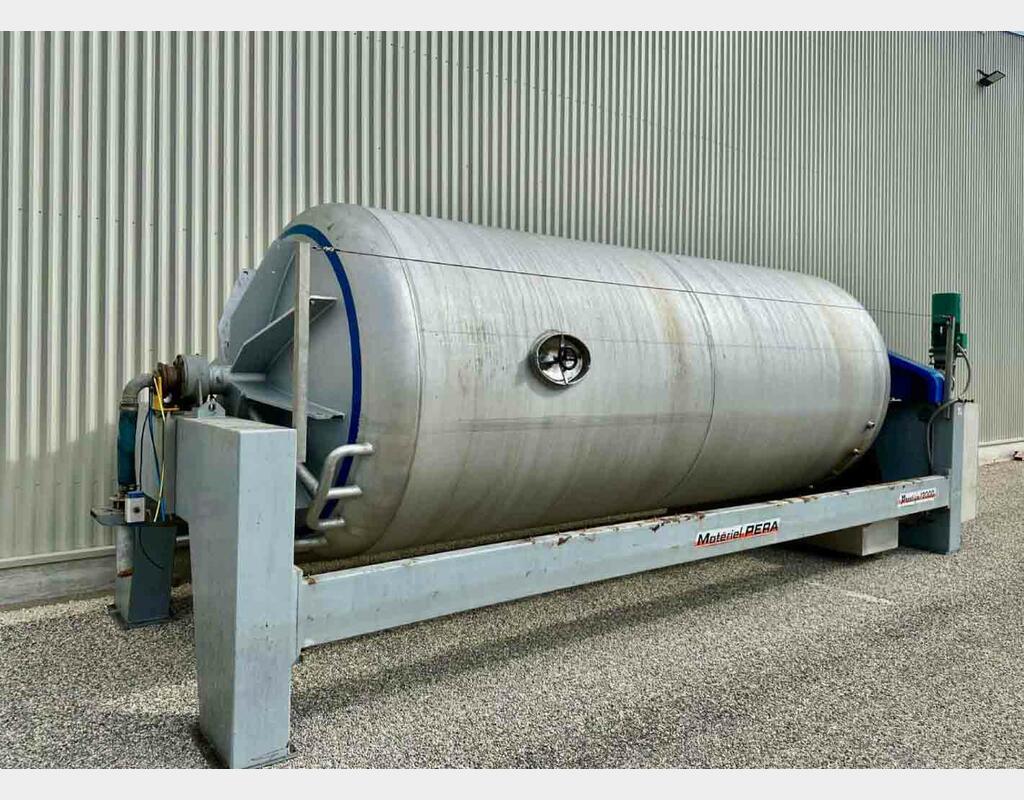

Closed cage pneumatic press - XPF 62 INERTIS - 007555

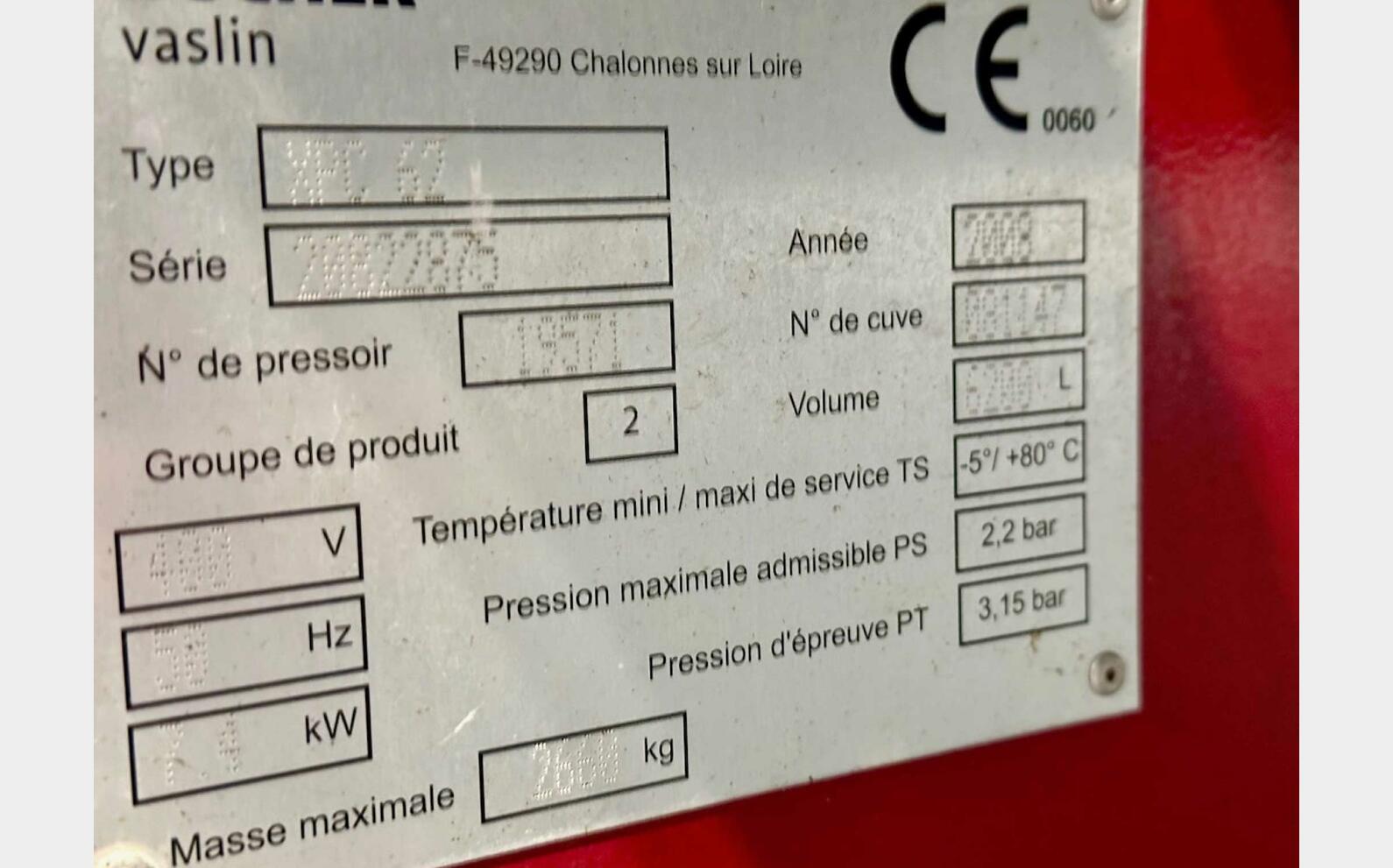

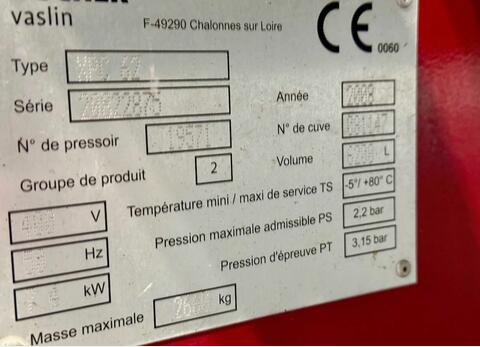

BUCHER

62 HL (6,200 litres)

Stock : 1

Detailed description :

BUCHER XPF 62 Inertys pneumatic press – 62 hL (6,200 L)

Second-hand – Year 2008

BUCHER XPF 62 pneumatic membrane press equipped with the Inertys process, designed for high-quality pressing in a controlled atmosphere (inert gas): ideal for wineries and estates seeking to limit oxidation and preserve the aromatic potential of their juices.

TECHNICAL FEATURES

- Brand/Model: BUCHER – XPF 62 INERTYS

- Type: closed cage pneumatic press, Inertys system (pressing under inert gas with recycling)

- Tank capacity: 62 hL – 6,200 L

- Year: 2008

- Serial number: 19 571

- Loading: axial loading Ø 120 mm (filling by screw, marc pump or adapted skip)

- Application * white, rosé and red wines – whole harvest, destemmed, fermented vats

INERTYS PROCESS – PRESSING UNDER CONTROLLED ATMOSPHERE

- Complete inerting of the press during the pressing cycle (tank, gas reserve, circuits)

- Use of inert gas (N2/CO2) with recycling, greatly limiting oxygen intake

- Protection of juices from the moment of filling: more stable colours, better preservation of aromas (particularly interesting for whites and rosés)

LOADING CAPACITIES (ORDERS OF MAGNITUDE)

- Whole grapes: ˜ 5,500–6,000 kg

- Destemmed grapes: ˜ 11,000–12,000 kg

- Pomace/fermented vats: ˜ 17,000–18,000 kg

*(approximate values, depending on density and grape variety)*

CONSTRUCTION

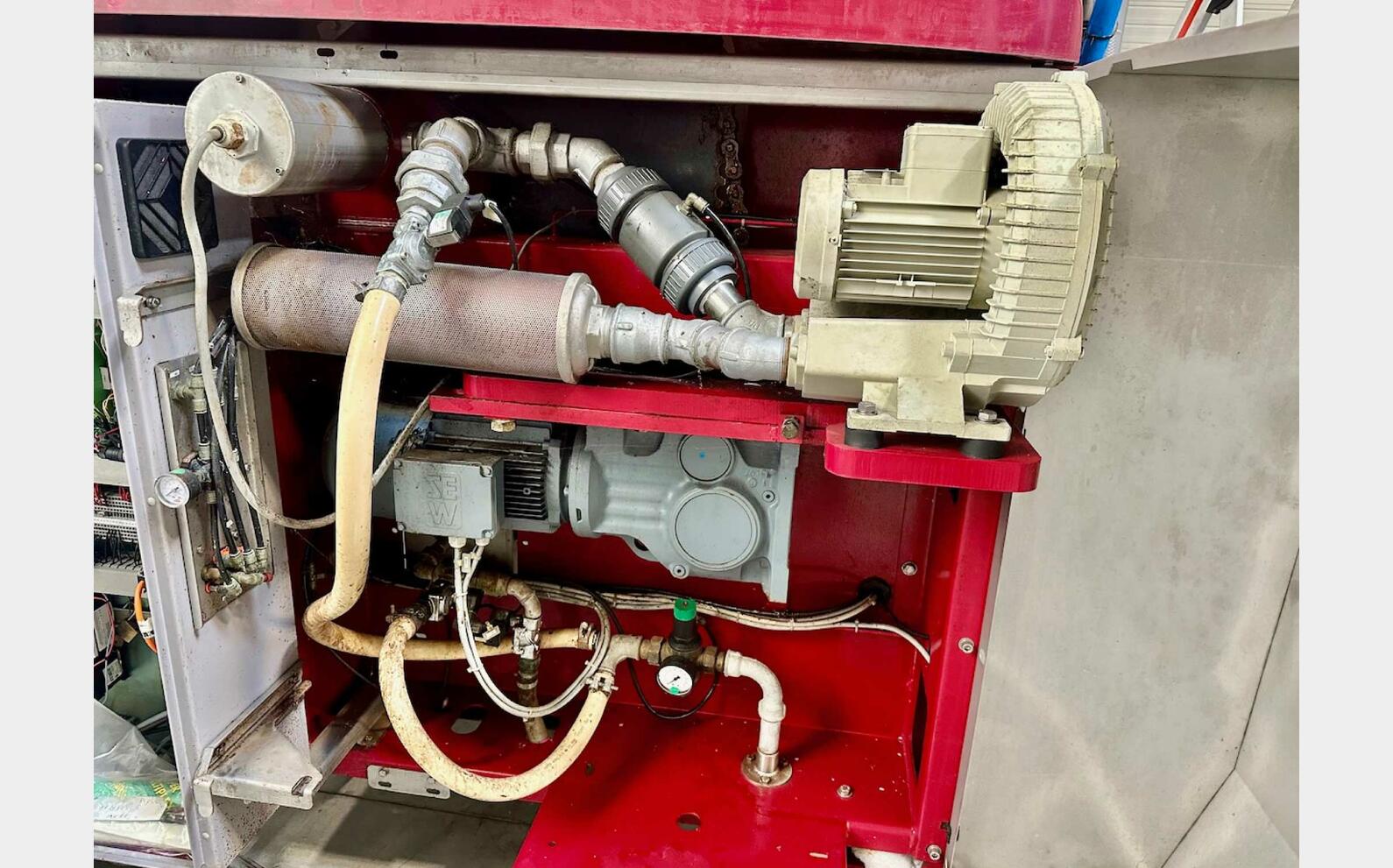

- Closed cylindrical stainless steel tank mounted on a supporting frame

- Internal pressing membrane (compressed air)

- Stainless steel drainage pipes for collecting juice in a dedicated collector

- Juice drainage chute/trough to pump or receiving tank

- Casing and peripheral guards for safe working and easy cleaning

LOADING – EMPTYING – DRAINAGE

- Axial loading Ø 120 mm: simple feeding from destemmer, conveyor belt or pomace pump

- Pomace emptying by opening door(s) and rotating the tank

- Juice outlets at the bottom, with stainless steel connections for connection to the tank room

CONTROLS AND AUTOMATION

- Electronic control panel (programming of pressing cycles)

- Automatic programmes + manual/semi-automatic mode (depending on configuration)

- Management of pressure levels, durations, raking, rotations

- Control of the Inertys circuit (inerting, gas recovery/recycling)

CONNECTIONS AND SERVICES

- Three-phase power supply (approx. 400 V – to be confirmed on nameplate)

- Compressed air supply for the membrane

- Connection to the inert gas network for the Inertys process

DIMENSIONS / FOOTPRINT (APPROXIMATE)

- Total length : ˜ 5,500–6,000 mm

- Width : ˜ 2,000–2,300 mm

- Height : ˜ 2,600–2,900 mm

ANNEXES

- Warranty : 1 campaign

- Compliance : CE standards compliant

Used BUCHER XPF 62 INERTYS press, in very good condition, offering high-performance pressing in a controlled atmosphere, perfectly suited to wineries looking for a high-quality, modern tool to enhance their juices.

_________________

TIPS AND NEWS

- Wine presses

Discover the advantages of second-hand wine presses. - Warranty

Guide to quality guarantees for industrial equipment.